TURNKEY SOLUTIONS

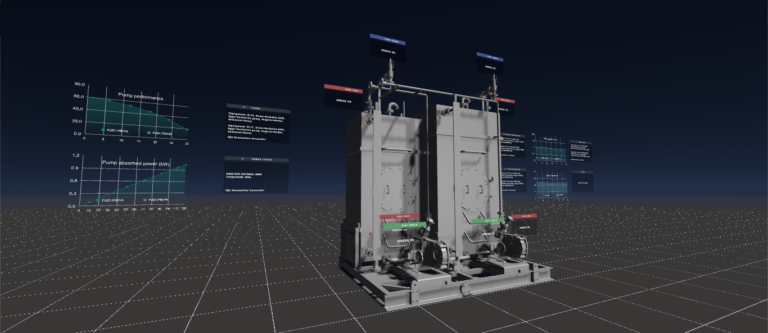

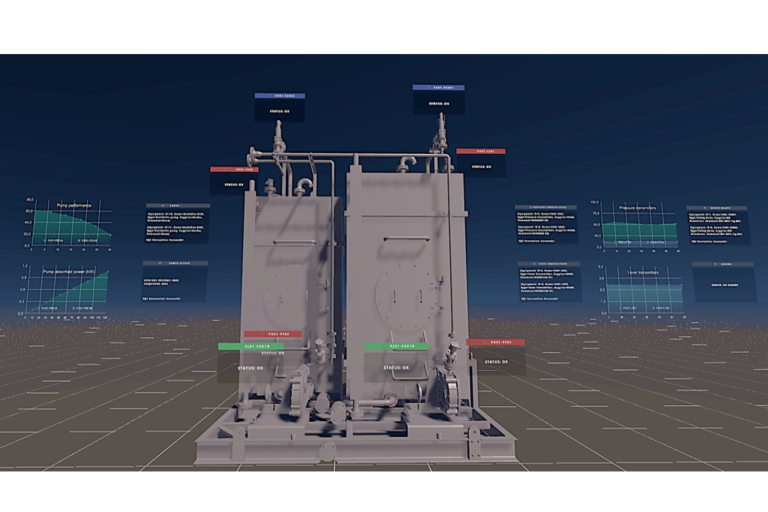

Visualize models and simulate operation within a virtual reality environment, but do not stop there...

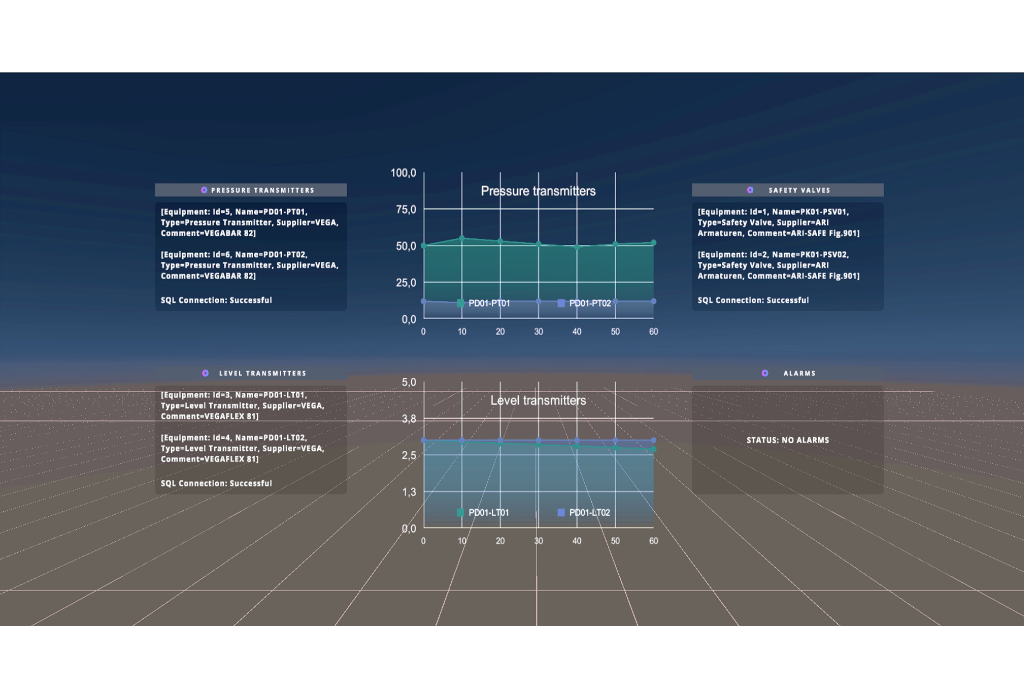

Stream real data and observe behavior, predict condition and likelihood of failure modes.

Let us know how we can help

An asset level digital twin parses and processes real time data streamed directly from the real world so as to create a dynamic, virtual, representation of the equipment being simulated. By creating a digital twin, it is possible to gather insight about potential ways to improve operations, increase efficiency or determine potential breakdown points before events happen. Lessons can be learnt from the digital twin which can be later applied to the real life installation, reducing process-related incidents and avoiding unplanned downtime, mitigating risk and associated costs, in consequence.

We introduce the digital twin paradigm in the following stages:

- Design: Simulation and visualization during the design phase can be used to verify and inspect the overall 3D design and make sure all parts fit together. The design review process can be undertaken remotely together with the client and/or end user to ensure that the design is deemed to be fit for purpose, in a virtual reality environment.

- System integration: 3D visualizations on a system level can verify constraints such as spatial footprint and physical connections. We can integrate the 3D model in a virtual reality environment together with a set of cloud scan data taken from the real life installation, allowing for the aforementioned verifications. Integration effort onsite and the associated downtime for the customer is reduced, as feasibility of installation can be verified beforehand at the virtual environment.

- Diagnostics: Observation of the digital twin, for example in a 3D visualization, can support troubleshooting. Augmented reality devices can provide field technicians with an overlay over the real equipment enabling the visualization of key operational parameters. Simulations can add non-observable data, such as key performance data of non-accessible parts.

- Prediction: Past and present operational and sensor data in combination with predictive algorithms provide insights into the condition of equipment and the likelihood of different failure modes. This helps plan rational maintenance and reduce unplanned downtime.

Besides specific deliverables, we can also provide general consultation and technical assistance services, as described below. Please keep reading and get in contact, we will be thrilled to hear from you and provide you with a complimentary consultation at no cost to you.

Get your free consultation

The challenges and pain points we specifically address

– Inefficient communication which may hinder or slow project development.

To mitigate this potential issue we offer local presence at your premises during the kick-off and early project stages, ensuring that the basic design requirements and preferences are well understood and accounted for.

We also offer a wide range of communication channels to ensure constant presence and availability so as to remain in close contact with your team, as well as access to secure data repositories to push project updates on a regular basis.

– Aggressive project timelines, scope variations and budget constraints.

We are acutely aware of the importance of upholding the contractual commitments, and the impact any deviations may have on your overall project scope. We offer weekly project updates detailing progress and, where appropriate, highlighting any deviations which have been detected, their causes, and our suggestions to mitigate their consequences. If we might fail to appropriately detect any measurable deviation, or act upon any detected deviations, we will voluntarily undertake to meet the obligations laid out in our professional guarantee as described below, in addition to whatever contractual terms might kick in.

– Overcoming a wide range of hurdles, pronto.

Whether a drawing needs to be promptly amended to accommodate an urgent request during plan approval, or a parcel is stuck in customs half way across the world due to incorrect or missing paperwork, or a new batch of PTFE coated bolting material is needed urgently at the installation site, we are here to help, seven days a week.

– Embracing new technology.

We constantly review and evaluate new software tools and technologies available in the market so as to be able to provide more complex scopes, be more flexible, and stay relevant.

As an example, we have recently deployed a set of tools enabling us to offer a virtual reality environment for design review and remote collaboration with clients and stakeholders, also acting as foundation for digital twin prototyping.

We can also deliver fully tested and configured environments for finite element modelling and analysis, based upon recognized open source packages, including benchmarks.

De-risking, performance measuring, and our professional guarantee

Our engineering deliverables and overall performance are covered by a comprehensive insurance policy that offers economic safeguard against a wide range of risks and uncertainties. Specific arrangements can be made on a project basis to extend the coverage, and policies are available upon request.

We guarantee that our practicing engineers will address your consultation to your satisfaction. They will also promptly return your emails, phone calls, or conference calls, within the same business hour, and fully addressing your concern or query. Where the query might require further action or consultation, or justifiable additional effort, clear estimates will be provided, and acted upon.

If we do not live up to any of these promises, or if you might feel that our performance has fallen short, we insist that you tell us, and we will make it right by scrambling to address any shortcomings, and crediting your account double the billable amount of the original consultation.

References

Getting in contact and your free consultation

We are interested in building a relationship with you. In order for you to have the opportunity of evaluating our response and performance, we are lowering the barrier to entry by offering a free consultation, no obligations or strings attached, where you can interact with our consulting engineers for up to 15 hours of billable work, which will be credited to your account, at no cost to you.

Just fill the form available on this page, and our team will be happy to get in contact with you within the next 24 hours.

Terms and conditions are simple:

No obligations on your part, implicit or otherwise. Fair use applies and we reserve the right to disengage at any time in case of abuse or misuse of this promotion, confirmed or otherwise. This offer expires on December 31st, 2022.

Contact Us

For a complimentary consultation, or to request a case study and additional information, call +34 644358624 or +44 7360 606849 or complete this form.

We look forward to hearing from you.