Thermal waste treatment is a critical component of modern marine waste management systems, offering an efficient and environmentally responsible method for disposing of waste generated on ships. However, the implementation of thermal waste treatment solutions can be capital-intensive, making cost-effectiveness a key consideration for ship operators and marine engineers.

he cost of implementing and operating a thermal waste treatment system is influenced by several factors, including the initial capital investment, operational expenses, maintenance requirements, and regulatory compliance. The initial capital investment covers the cost of equipment, such as incinerators or pyrolysis units, as well as auxiliary systems like flue gas treatment and energy recovery units. Operational expenses include fuel consumption, electricity usage, and labor costs, while maintenance costs encompass routine inspections, component replacements, and repairs. Regulatory compliance costs arise from the need to meet stringent emission standards and waste disposal regulations. Understanding these cost drivers is essential for identifying opportunities to optimize the system and reduce overall expenses.

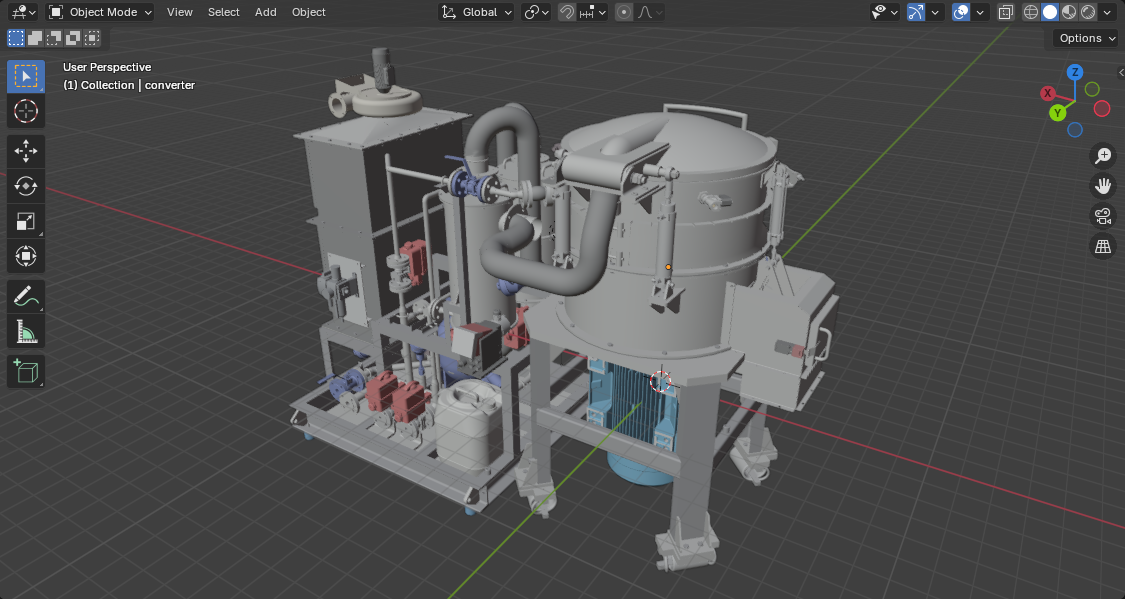

Design optimization is a critical step in developing cost-effective thermal waste treatment solutions. Engineers must carefully balance performance, reliability, and cost to create a system that meets operational requirements without unnecessary expenses. One approach is to modularize the system, allowing for scalability and flexibility. Modular designs enable ship operators to install only the capacity they need, reducing upfront costs and allowing for future expansion if required. Additionally, the use of standardized components and off-the-shelf equipment can lower procurement and maintenance costs compared to custom-designed solutions.

The selection of materials is another important consideration. While high-temperature-resistant materials, such as refractory ceramics and stainless steel, are essential for durability, engineers should evaluate cost-effective alternatives that meet performance requirements. For example, advanced coatings and linings can extend the lifespan of less expensive materials, reducing the need for frequent replacements. The design should also minimize energy losses through effective insulation and heat recovery mechanisms, further enhancing cost efficiency.

Operational efficiency plays a significant role in reducing the ongoing costs of thermal waste treatment systems. One of the primary operational expenses is fuel consumption, which can be optimized through careful system design and operation. For incineration systems, the use of waste-derived fuels, such as shredded plastics or oily waste, can reduce reliance on external fuel sources and lower operating costs. These materials have high calorific values and can be effectively combusted, providing a dual benefit of waste disposal and energy generation.

Automation and advanced control systems can also improve operational efficiency by optimizing combustion parameters, such as temperature, airflow, and feed rates. These systems ensure that the thermal process operates at peak efficiency, minimizing fuel consumption and reducing emissions. Additionally, real-time monitoring and diagnostics enable proactive maintenance, preventing costly downtime and extending the system’s lifespan.

Energy recovery is a key feature of cost-effective thermal waste treatment solutions, as it allows for the capture and utilization of heat generated during the process. The recovered energy can be used for various onboard applications, such as heating, power generation, or desalination, reducing the ship’s overall energy demand and operational costs. Heat exchangers and steam generators are commonly used to recover thermal energy from flue gases, converting it into usable forms such as hot water or steam.

In addition to direct energy recovery, some thermal treatment systems can produce syngas or biochar through pyrolysis. These byproducts can be used as alternative fuels or soil amendments, providing additional value and offsetting operational costs. Engineers should explore integrated energy recovery solutions that maximize the utilization of waste heat and byproducts, enhancing the overall cost-effectiveness of the system.

Innovative technologies offer promising opportunities for cost-effective thermal waste treatment. For example, plasma gasification is an advanced thermal process that uses high-temperature plasma to convert waste into syngas and vitrified slag. While the initial investment in plasma gasification systems can be high, their ability to handle a wide range of waste types and produce valuable byproducts can result in long-term cost savings. Similarly, hybrid systems that combine thermal treatment with mechanical or biological processes can improve efficiency and reduce costs by preprocessing waste or recovering additional resources.

Another cost-effective solution is the use of compact and portable thermal treatment units, which are particularly suitable for smaller vessels or those with limited space. These units are designed for easy installation and operation, reducing both capital and operational expenses. Additionally, collaborative waste management initiatives, such as shared treatment facilities for multiple vessels in a port, can lower costs by spreading the investment and operational burden across several stakeholders.

Effective maintenance and lifecycle cost management are essential for ensuring the long-term cost-effectiveness of thermal waste treatment systems. Engineers should design systems with ease of maintenance in mind, incorporating features such as accessible inspection points, modular components, and durable materials. Predictive maintenance technologies, such as sensors and data analytics, can help identify potential issues before they escalate, reducing repair costs and downtime.

Lifecycle cost management involves evaluating the total cost of ownership, including initial investment, operational expenses, and end-of-life disposal. By considering the entire lifecycle, engineers can make informed decisions that balance upfront costs with long-term savings. For example, investing in higher-quality components may result in lower maintenance and replacement costs over time, ultimately reducing the total cost of ownership.

Cost-effective thermal waste treatment solutions are essential for sustainable and efficient marine waste management. By optimizing system design, improving operational efficiency, recovering energy, and leveraging innovative technologies, solutions that meet regulatory requirements while minimizing costs can be developed. The integration of modular designs, alternative fuels, and advanced control systems further enhances cost efficiency, ensuring that thermal waste treatment remains a viable and economical option for ship operators.