Thermal waste treatment devices are critical components in modern marine engineering, designed to manage and dispose of waste generated on ships in an environmentally responsible and efficient manner. These devices utilize high-temperature processes to break down waste materials, reducing their volume and converting them into inert byproducts. The design of such systems requires a thorough understanding of thermal processes, waste characteristics, regulatory requirements, and operational constraints.

Knowing the characteristics of the waste and the applicable regulatory framework is of primary importance in designing a thermal waste treatment unit. Onboard wastes comprised a variety of materials, including organic wastes, plastics, paper products, and hazardous waste, which all have different thermal properties and treatments. It is of great importance to analyze factors such as composition of waste, moisture content, calorific value, and potential emissions in order to establish the best mode of treatment. Furthermore, the design should also meet international standards, e.g., those established by the International Maritime Organization (IMO) and the Marine Pollution (MARPOL) Convention, which govern waste management in marine ecosystems. These standards call for the minimization of noxious emissions, e.g., dioxins, furans, and particulate matter, and mandate the treatment of waste to reduce environmental effects.

Thermal waste management technologies fall into one of two fundamental technological approaches: pyrolysis or incineration. Incineration is characterized by the high-temperature combustion of waste, usually in the range 850°C to 1200°C, in an oxygen-rich environment, with the final outcome being the conversion of waste into ash, flue gas, and thermal energy. Pyrolysis, on the other hand, is the heat decomposition of waste in an oxygen-free environment, yielding syngas, biochar, and liquid fuel products. The choice of technology is based on waste composition, byproducts desired, and operational constraints. Incineration, for example, is suitable for blended waste streams, while pyrolysis is most suitable for organic wastes and plastics. Each technology’s strengths and weaknesses must be evaluated so that the best fit for the ship’s waste management needs can be selected.

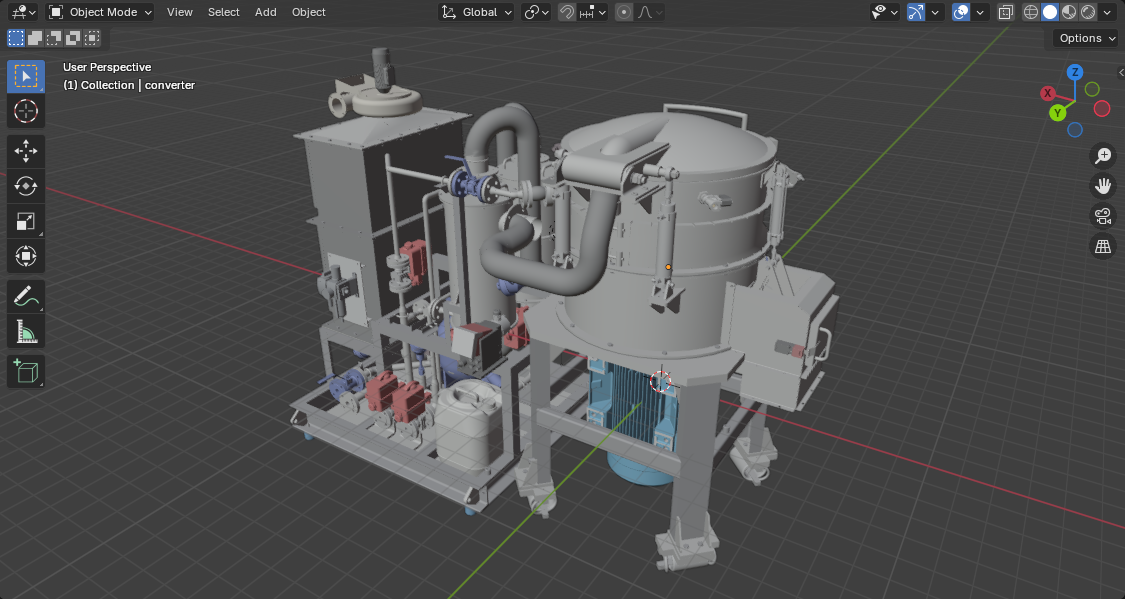

The design of a thermal waste treatment device includes several key aspects, each playing a critical role in the effectiveness of the system. The waste feed system is responsible for the orderly addition of waste to the treatment chamber. This system must be designed to handle varied waste sizes and compositions while preventing blockages and ensuring consistent feed rates. The treatment chamber, in which the thermal process takes place, must be constructed from materials resistant to high temperatures, like refractory ceramics or stainless steel, to resist the high temperature and corrosive byproducts produced.

Pyrolysis or combustion needs a dependable heat source, which is usually supplied by burners or electric heaters. The heat source must be capable of sustaining the desired temperature range with the capability to adjust to variations in waste composition and feed rates. The flue gas treatment system plays a critical role in eliminating dangerous emissions, including particulate matter, acidic gases, and volatile organic compounds (VOCs). The system typically consists of a number of components, such as cyclones, scrubbers, and filters, that act in harmony to purify the flue gas prior to its release to the environment.

One benefit of thermal waste treatment is the potential for energy recovery. The heat energy produced in the process may be utilized to create steam or hot water, which may be utilized for different applications such as onboard heating, power generation, or other uses. Incorporating heat exchangers and energy recovery systems into the design can enhance the efficiency of energy and lower the ship’s overall fuel consumption. Furthermore, it is essential that the system is designed with minimal heat losses by using insulation and optimal heat transfer mechanisms.

Safety is a top priority in the innovation of thermal waste treatment technology. With high temperatures and the potential for hazardous emissions, it is necessary to include robust safety features such as temperature controls, pressure relief valves, and emergency shutdown systems. The design should also be focused on blocking the release of harmful substances into the immediate environment, thus ensuring compliance with emission standards. It is critical to conduct a thorough risk assessment to identify potential hazards and implement measures to mitigate them effectively.

Environmental considerations extend beyond emissions control to include byproduct management, such as ash and slag. Byproducts must be stored and disposed of properly in accordance with regulations. Design must incorporate ash removal systems and storage tanks to facilitate handling and disposal of byproducts.

A thermal waste treatment unit must take into account the operational and maintenance needs to achieve long-term operation and reliability. The system must be designed for simplicity of operation, such as controls that are straightforward and automated mechanisms reducing the necessity for human involvement. Maintenance access points must be deliberately positioned for convenient inspection, cleaning, and part replacement. The availability of spare parts and consumables must be taken into account, so that the system can be adequately maintained over its entire operating life.

The development of a thermal waste treatment unit for shipboard use is a challenging and multidisciplinary activity involving careful attention to waste characteristics, compliance with regulatory requirements, and operational limitations. Through the proper choice of technology, inclusion of main components, maximum energy efficiency, and safety and environmental considerations, waste management systems that are both effective in their function and minimize their environmental footprint can be achieved. The incorporation of energy recovery and maintenance-suitable features increases the value of the system further, leading to increased overall maritime operation sustainability and efficiency.