Certifying offshore containers to DNV (Det Norske Veritas) standards is a critical process that ensures the safety, reliability, and compliance of these containers with internationally recognized guidelines. Offshore containers are subjected to harsh environmental conditions and demanding operational requirements, making their certification essential for safeguarding personnel, equipment, and the environment. DNV, a leading classification society, provides a comprehensive framework for the design, fabrication, testing, and ongoing inspection of offshore containers.

The first step in the certification process of offshore containers under the DNV standards is to understand the exact requirements expressed in DNV’s rules and guidelines. The main document governing offshore containers is DNV 2.7-1, “Offshore Containers,” which provides detailed specifications on design, material, fabrication, testing, and marking. The standard ensures that containers can resist dynamic loads and environmental conditions in offshore operations, such as wave-induced motions, forces due to wind, and temperatures. Engineers should be familiar with the standard’s requirements, which include load calculation, structural strength, lifting and securing provisions, and safety requirements.

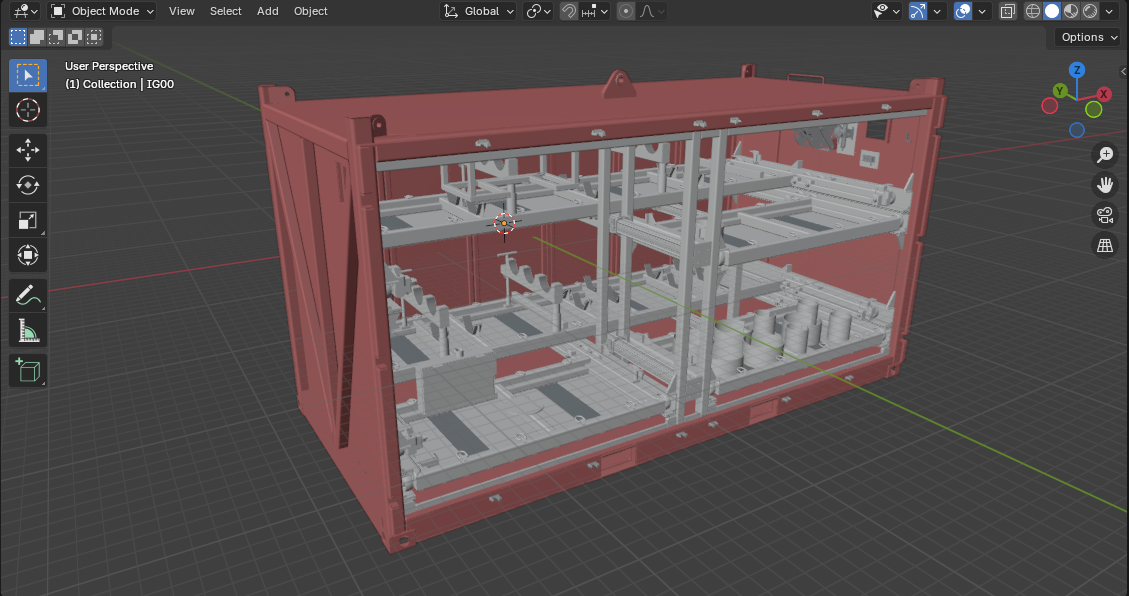

Certification begins at the design phase, where the container’s design must be approved and examined by DNV. Comprehensive design documentation will be prepared, e.g., drawings, calculations, and specifications, demonstrating compliance with DNV 2.7-1. The main design considerations are the structural strength of the container, lifting points, corner fittings, and securing arrangements. The design will take into account the maximum loads the container will encounter during lifting, stacking, and transportation, and the environmental conditions it will encounter.

Upon completion of design documentation, it is presented to DNV for scrutiny. The engineers at DNV will go through the design to verify whether it has achieved the desired standards and request further information or amendments if needed. On approval, a Design Approval Certificate is issued by DNV, which is a necessary requirement prior to moving into the fabrication stage.

Offshore container manufacturing needs to be subjected to rigorous quality control to be in compliance with DNV requirements. The manufacturing needs to be conducted by qualified workshops that have experience in the production of offshore equipment. Materials utilized, like steel for framing and plating, need to adhere to the stipulated mechanical and chemical properties as per DNV 2.7-1. It is essential that welding procedures and personnel be qualified under the established standards, and non-destructive test (NDT) techniques like ultrasonic testing (UT) and magnetic particle inspection (MPI) are used to examine weld integrity.

Under the manufacturing process, checks can be carried out by DNV inspectors to verify adherence to the accepted design and quality control measures. Such checks guarantee that the container is being produced according to the set standards and that any discrepancies are addressed in good time. Fabrication records, such as material certificates, welding procedures, and inspection reports, have to be maintained and forwarded to DNV for verification.

Following fabrication, the offshore container is put through a series of tests to ascertain its structural strength and function. The test process typically includes a visual examination, dimensional verification, and functional testing of doors, hatches, and securing arrangements. The most significant test is the prototype load test, where the container is loaded with 2.5 times its maximum gross weight to verify that it has the capacity to withstand the dynamic loads experienced during lifting and transportation.

Apart from the four-point load test, DNV also usually demands additional prototype unit testing in the form of a drop test or two-point load test. All the test results have to be duly documented and submitted to DNV for evaluation. If all the tests are passed, DNV then provides a Certificate of Conformity, stating that the container is in conformance with the necessary standards and safe for offshore operational service.

DNV-certified offshore containers must be marked with required information to ensure safe handling and traceability. The marking typically includes the maximum gross weight of the container, tare weight, serial number, and DNV certificate number. Lifting points and corner fittings must also be marked to indicate their safe working load limits. Markings must be clear and long-lasting so that they remain visible for the lifetime of the container.

Certification to DNV standards is not an one-off process but instead needs to be achieved on an ongoing basis with the help of periodic surveys and maintenance. Regular inspections are enforced by DNV every 12 months to monitor the condition of the container and guarantee it fits for service. Such surveys incorporate visual checks for the structure, lifting points, and securing arrangement along with the functional testing of doors and hatches. Any deterioration or degradation must be remedied forthwith, and repairs thereof must be documented and approved by DNV.

Apart from the annual audits, DNV may require interim assessments or additional inspections if the container sustains severe damage or modifications. Proper maintenance, which includes periodic cleaning, lubrication, and protection against corrosion, is crucial for extending the operating life of the container while maintaining its certification.

Offshore container certification in accordance with DNV standards is a thorough and extensive procedure that guarantees the safety, reliability, and compliance of these valuable assets. Through compliance with DNV’s design, fabrication, testing, and inspection requirements, manufacturers and engineers can create containers that can endure the severe conditions associated with offshore operations. Periodic inspections and maintenance guarantee continued compliance, thereby certifying the container’s ongoing fitness for use in operations.