Offshore containers are specialized units designed to meet the rigorous demands of offshore environments, such as oil rigs, wind farms, and marine construction sites. While they may resemble regular shipping containers in appearance, offshore containers are engineered to withstand extreme conditions, adhere to stringent safety standards, and provide reliable performance in some of the harshest environments on Earth. These unique requirements contribute to their significantly higher cost compared to regular containers.

Why Offshore Containers Are More Expensive Than Regular Containers

Offshore containers are specialized units designed to meet the rigorous demands of offshore environments, such as oil rigs, wind farms, and marine construction sites. While they may resemble regular shipping containers in appearance, offshore containers are engineered to withstand extreme conditions, adhere to stringent safety standards, and provide reliable performance in some of the harshest environments on Earth. These unique requirements contribute to their significantly higher cost compared to regular containers. This article delves into the key factors that make offshore containers more expensive, providing a comprehensive understanding of the underlying reasons.

Stringent Design and Engineering Standards

One of the primary reasons for the higher cost of offshore containers is the stringent design and engineering standards they must meet. Offshore containers are subject to rigorous certification processes by recognized bodies such as DNV GL, ABS, and Lloyd’s Register. These certifications ensure that the containers can withstand the extreme conditions encountered in offshore environments, including high winds, heavy seas, and corrosive saltwater. The design process involves extensive engineering analysis, including finite element analysis (FEA) to simulate stress and load conditions, ensuring the container’s structural integrity. This level of engineering precision and certification adds to the overall cost.

High-Quality Materials and Construction

Offshore containers are constructed using high-quality materials that offer superior durability and corrosion resistance. Common materials include corrosion-resistant steel, such as Corten steel, and high-strength aluminum alloys. These materials are more expensive than the standard steel used in regular containers but are essential for withstanding the harsh offshore environment. Additionally, offshore containers often feature advanced coatings and surface treatments, such as epoxy or polyurethane paints, to further enhance their resistance to corrosion and environmental degradation. The use of premium materials and protective treatments significantly increases the cost of production.

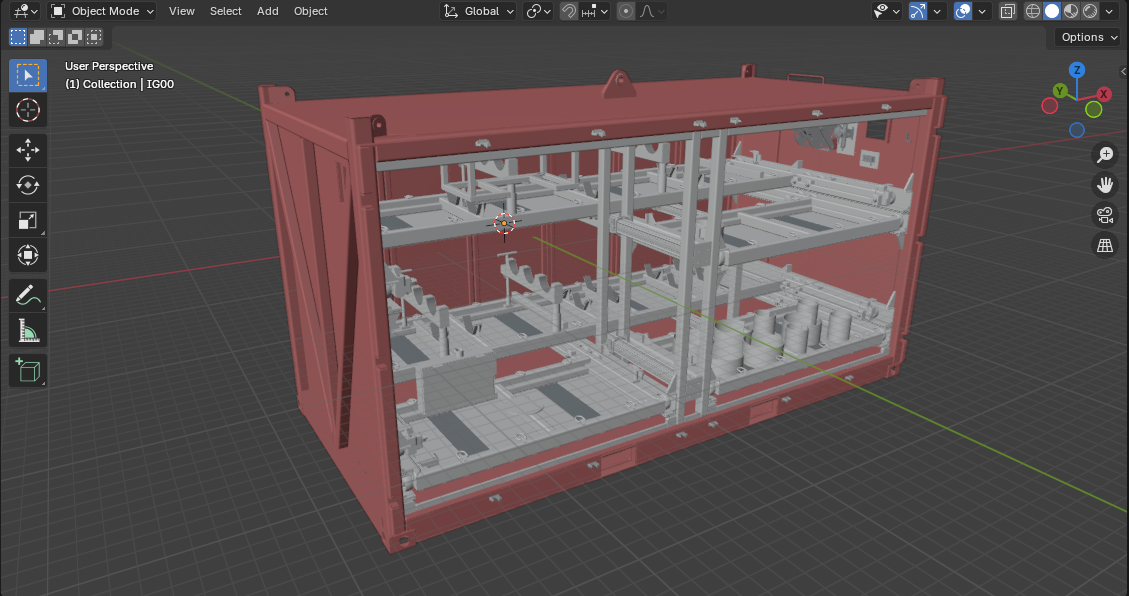

Specialized Features and Customization

Offshore containers are often customized to meet specific operational requirements, which adds to their cost. These containers may include specialized features such as reinforced flooring, heavy-duty shelving, integrated workbenches, and climate control systems. Customization allows the containers to be tailored for specific functions, such as workshops, storage, or living quarters, but it also involves additional design and manufacturing efforts. The need for bespoke solutions to address unique operational challenges further drives up the cost of offshore containers.

Enhanced Safety and Compliance

Safety is a paramount concern in offshore operations, and offshore containers are designed with a range of enhanced safety features. These may include explosion-proof lighting, fire suppression systems, secure latching mechanisms, and ergonomic design elements. Compliance with international safety standards and regulations, such as those set by the International Maritime Organization (IMO) and the International Organization for Standardization (ISO), requires rigorous testing and certification. The incorporation of advanced safety features and the costs associated with compliance contribute to the higher price of offshore containers.

Robust Structural Integrity

Offshore containers are built to withstand significant mechanical stresses, including heavy loads, rough handling, and the dynamic forces encountered during transportation and deployment. The structural integrity of these containers is reinforced through the use of thicker steel plates, additional bracing, and robust corner castings. These enhancements ensure that the containers can endure the rigors of offshore operations without compromising their performance or safety. The additional materials and engineering required to achieve this level of structural integrity increase the overall cost.

Transportation and Logistics

The transportation and logistics of offshore containers also contribute to their higher cost. Offshore containers are often transported to remote and challenging locations, requiring specialized handling equipment and vessels. The weight and size of these containers, combined with the need for secure and efficient transportation, add to the logistical complexity and cost. Additionally, the need for insurance and permits for transporting oversized or heavy containers further increases the overall expense.

Maintenance and Longevity

While offshore containers are more expensive upfront, they are designed for long-term use with minimal maintenance. The high-quality materials and construction methods employed in their manufacture ensure that they can withstand the harsh offshore environment for extended periods. This longevity reduces the need for frequent repairs and replacements, offering long-term cost savings. However, the initial investment in durable materials and construction techniques contributes to the higher price of offshore containers.

Conclusion

Offshore containers are more expensive than regular containers due to a combination of stringent design and engineering standards, high-quality materials, specialized features, enhanced safety and compliance, robust structural integrity, complex transportation and logistics, and long-term durability. These factors ensure that offshore containers can meet the unique challenges of offshore environments, providing reliable and safe performance in some of the most demanding conditions. While the initial cost is higher, the long-term benefits of reduced maintenance, extended service life, and enhanced safety often justify the investment. Understanding the reasons behind the higher cost of offshore containers is essential for making informed decisions and ensuring the success of offshore operations.