The offshore industry is continually evolving, driven by the need for greater efficiency, safety, and sustainability. Offshore containers, essential for the storage, transportation, and deployment of equipment and tools, have seen significant advancements in design and functionality. These innovations are aimed at addressing the unique challenges posed by offshore environments, such as harsh weather conditions, limited space, and stringent safety regulations.

Smart Containers: Integration of IoT and Advanced Monitoring Systems

One of the most significant innovations in offshore container design is the integration of Internet of Things (IoT) technology and advanced monitoring systems. Smart containers are equipped with sensors and connected devices that provide real-time data on various parameters, such as temperature, humidity, pressure, and location. This data is transmitted to a central monitoring system, allowing for continuous tracking and management of the container’s contents and condition. IoT-enabled containers enhance operational efficiency by enabling predictive maintenance, reducing downtime, and ensuring the integrity of sensitive equipment. Additionally, these systems improve safety by providing early warnings of potential issues, such as leaks or structural failures.

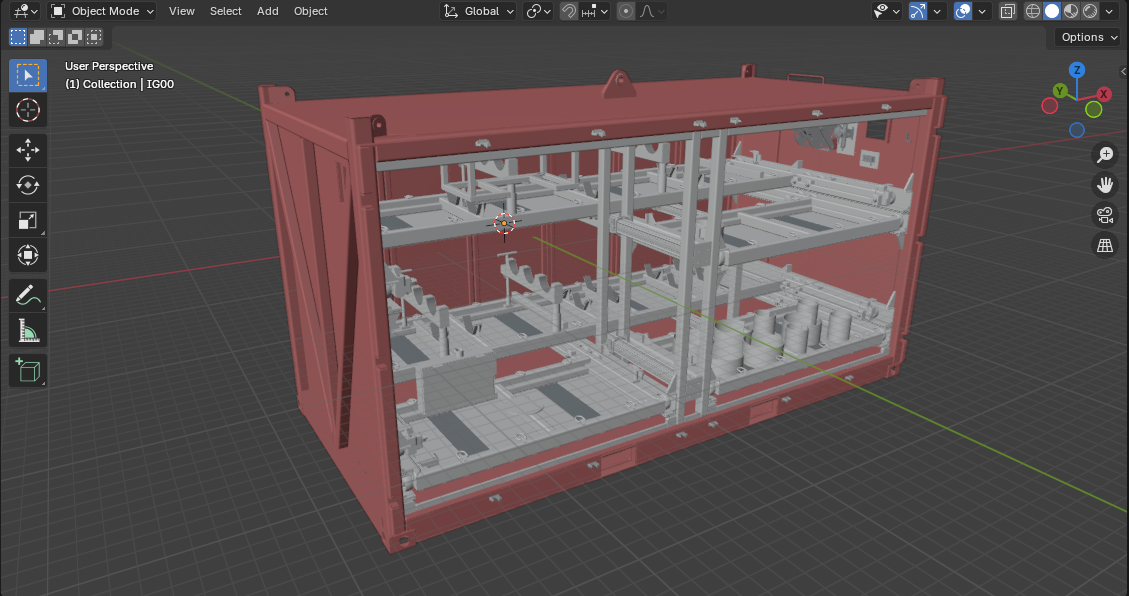

Modular and Customizable Designs

Modularity and customization have become key trends in offshore container design. Modern containers are designed with interchangeable components and flexible layouts, allowing for easy reconfiguration to meet specific operational needs. This modular approach enables offshore operators to optimize space utilization and adapt containers for different functions, such as workshops, storage, or living quarters. Customizable features, such as adjustable shelving, removable partitions, and specialized compartments, further enhance the versatility of these containers. The ability to tailor containers to specific requirements not only improves efficiency but also reduces the need for multiple specialized units, resulting in cost savings.

Enhanced Durability and Corrosion Resistance

Advancements in materials science have led to the development of offshore containers with enhanced durability and corrosion resistance. New alloys and composite materials are being used to construct containers that can withstand the extreme conditions of offshore environments. For example, high-performance coatings and surface treatments, such as nano-coatings and advanced polymer composites, provide superior protection against saltwater, UV radiation, and mechanical wear. These innovations extend the service life of containers, reduce maintenance requirements, and ensure reliable performance in the harshest conditions.

Energy-Efficient and Sustainable Designs

Sustainability is a growing focus in the offshore industry, and container design is no exception. Energy-efficient containers are being developed with features such as insulated walls, energy-efficient lighting, and solar panels. These designs reduce energy consumption and minimize the environmental impact of offshore operations. Additionally, the use of recyclable and eco-friendly materials in container construction is becoming more prevalent. Sustainable design practices not only align with environmental regulations but also contribute to the overall sustainability goals of offshore projects.

Improved Safety Features

Safety is paramount in offshore operations, and recent innovations in container design have introduced a range of enhanced safety features. Containers are now equipped with advanced fire suppression systems, explosion-proof lighting, and reinforced structures to withstand extreme conditions. Additionally, ergonomic design elements, such as easy-access doors, non-slip flooring, and secure latching mechanisms, improve the safety and usability of containers. These features help to prevent accidents and injuries, ensuring a safer working environment for offshore personnel.

Lightweight and High-Strength Materials

The use of lightweight and high-strength materials is another significant innovation in offshore container design. Advanced materials, such as high-strength aluminum alloys and carbon fiber composites, offer the dual benefits of reduced weight and increased structural integrity. Lightweight containers are easier to transport and handle, reducing logistical challenges and costs. At the same time, the high strength of these materials ensures that containers can withstand the rigors of offshore operations, including heavy loads and rough seas. This combination of lightweight and high-strength properties enhances the overall efficiency and performance of offshore containers.

Integrated Logistics and Tracking Systems

Innovations in logistics and tracking systems have revolutionized the management of offshore containers. Integrated systems that combine GPS tracking, RFID technology, and cloud-based software platforms enable real-time monitoring and management of container movements. These systems provide visibility into the location, status, and condition of containers throughout the supply chain, improving coordination and reducing the risk of lost or misplaced units. Enhanced logistics and tracking capabilities streamline operations, reduce downtime, and ensure that containers are available when and where they are needed.

Conclusion

The latest innovations in offshore container design are driving significant improvements in efficiency, safety, and sustainability. Smart containers with IoT integration, modular and customizable designs, enhanced durability and corrosion resistance, energy-efficient and sustainable features, improved safety elements, lightweight and high-strength materials, and integrated logistics and tracking systems are transforming the way offshore operations are conducted. These advancements not only address the unique challenges of offshore environments but also contribute to the overall success and sustainability of offshore projects. As the industry continues to evolve, ongoing innovation in container design will play a crucial role in meeting the demands of modern offshore operations.