The use of offshore containers and cargo baskets in the oil and gas industry is governed by a comprehensive framework of international standards, national regulations, and industry best practices. These regulations are essential to ensure the safety, reliability, and environmental sustainability of offshore operations, which often take place in some of the most challenging and hazardous environments on Earth. Compliance with these regulations is not only a legal requirement but also a critical factor in minimizing risks to personnel, assets, and the environment.

International Standards and Regulatory Bodies

The design, fabrication, and usage of offshore containers and cargo baskets are primarily guided by international standards developed by organizations such as the International Organization for Standardization (ISO), the International Maritime Organization (IMO), and classification societies like Det Norske Veritas (DNV), the American Bureau of Shipping (ABS), and Lloyd’s Register. These standards provide a globally recognized framework for ensuring the structural integrity, safety, and performance of offshore containers and cargo baskets.

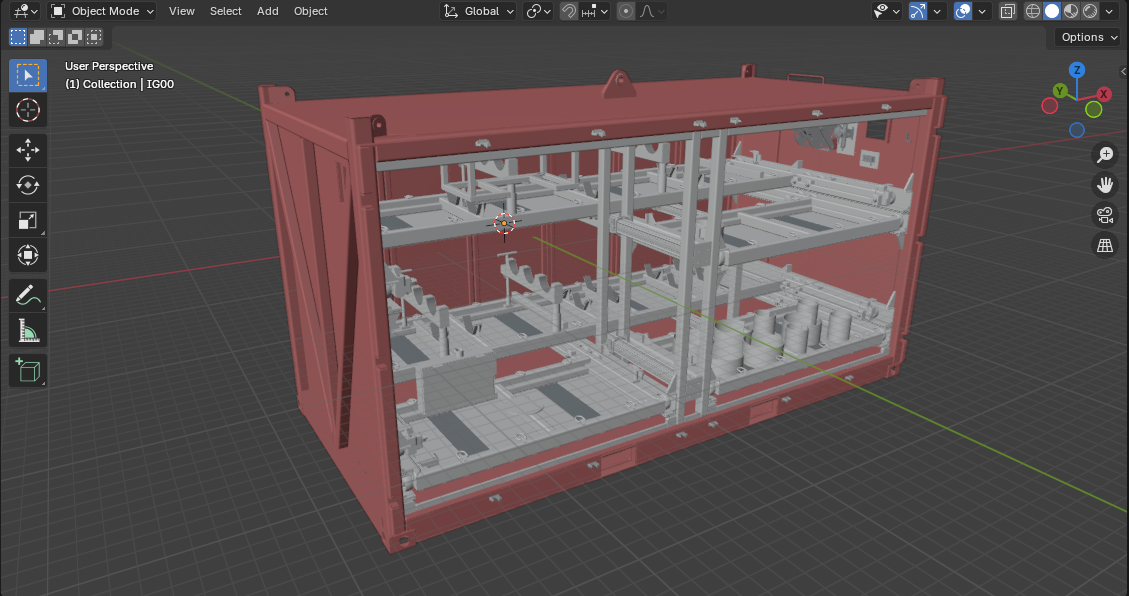

One of the most widely referenced standards for offshore containers is ISO 10855, which outlines the requirements for the design, fabrication, and testing of offshore containers. This standard covers various aspects such as load analysis, material selection, and structural design, ensuring that containers can withstand the dynamic forces and environmental conditions encountered in offshore environments. For cargo baskets, standards such as ISO 18647 provide guidelines for their design and usage, focusing on structural integrity, lifting points, and safety features.

The IMO plays a crucial role in regulating the transportation of hazardous materials by sea through the International Maritime Dangerous Goods (IMDG) Code. This code provides detailed guidelines for the safe handling, stowage, and transportation of hazardous goods, including the use of specialized containers and cargo baskets. Compliance with the IMDG Code is mandatory for all offshore containers and cargo baskets used to transport hazardous materials.

National Regulations and Regional Variations

In addition to international standards, offshore containers and cargo baskets must comply with national regulations specific to the region where they will be used. For example, in the United States, the Bureau of Safety and Environmental Enforcement (BSEE) regulates offshore oil and gas operations, including the use of containers and cargo baskets. BSEE’s regulations focus on safety systems, environmental protection, and operational integrity, requiring operators to submit detailed plans and undergo rigorous inspections.

In the European Union, offshore containers and cargo baskets must comply with the Offshore Safety Directive, which establishes minimum requirements for the prevention of major accidents and the protection of workers and the environment. Similarly, in regions such as the North Sea, the Norwegian Petroleum Safety Authority (PSA) and the UK Health and Safety Executive (HSE) enforce stringent regulations to ensure the safety and reliability of offshore installations.

These national and regional regulations often build upon international standards but may include additional requirements tailored to the specific risks and conditions of the area. For instance, regions prone to extreme weather or seismic activity may impose stricter design criteria to ensure the resilience of offshore containers and cargo baskets.

Certification and Inspection Processes

The certification and inspection of offshore containers and cargo baskets are critical steps in ensuring their compliance with regulatory requirements. The certification process typically begins with a design review, where the container or cargo basket’s design is evaluated against applicable standards and regulations. This review includes an assessment of structural calculations, material specifications, and safety systems to ensure that the unit meets the required criteria.

Once the design is approved, the fabrication process is closely monitored to ensure compliance with the approved specifications. Inspections are conducted at various stages of fabrication, including material testing, welding, and assembly. Non-destructive testing (NDT) methods, such as ultrasonic testing, radiographic testing, and magnetic particle inspection, are used to detect any defects or weaknesses in the structure.

After fabrication is complete, the container or cargo basket undergoes a series of tests to verify its performance under simulated offshore conditions. These tests may include load testing, where the unit is subjected to its maximum working load, and environmental testing, where it is exposed to conditions such as salt spray and extreme temperatures. Upon successful completion of these tests, the unit is issued a certificate of conformity by the classification society or regulatory authority.

Operational and Maintenance Regulations

The usage of offshore containers and cargo baskets is also subject to operational and maintenance regulations to ensure their ongoing safety and performance. Operators are required to conduct regular inspections and maintenance of these units, documenting any issues and addressing them promptly. Inspections should be carried out by qualified personnel and include checks for structural damage, corrosion, and wear and tear.

Maintenance practices must adhere to the manufacturer’s guidelines and regulatory requirements, ensuring that any repairs or modifications are carried out using appropriate materials and techniques. Regular maintenance helps to prevent accidents, reduce downtime, and extend the service life of the containers and cargo baskets.

Environmental and Sustainability Considerations

Environmental and sustainability considerations are increasingly important in the regulation of offshore containers and cargo baskets. Regulations such as the International Convention for the Prevention of Pollution from Ships (MARPOL) and the Offshore Safety Directive require operators to minimize the environmental impact of their activities. This includes reducing emissions, managing waste, and preventing oil spills.

Offshore containers and cargo baskets must be designed and operated in a manner that minimizes their environmental footprint. This includes the use of environmentally friendly materials, energy-efficient systems, and waste management solutions. For example, containers used for hazardous materials may be equipped with spill containment systems and chemical-resistant linings to prevent leaks and spills.

Conclusion

The use of offshore containers and cargo baskets in the oil and gas industry is subject to a complex and stringent regulatory framework that ensures their safety, reliability, and environmental sustainability. Compliance with international standards, national regulations, and industry best practices is essential to minimize risks to personnel, assets, and the environment. By adhering to these regulations and incorporating advanced engineering techniques, the offshore industry can continue to develop innovative and efficient solutions for the safe and sustainable transportation and storage of equipment and supplies. The rigorous certification and inspection processes further reinforce the integrity of offshore containers and cargo baskets, providing confidence to operators and stakeholders alike.