Offshore containers and cargo baskets serve as critical equipment in offshore operations, facilitating the safe transport of goods, materials, and equipment between offshore installations and supply vessels. DNV certification ensures these units meet stringent safety and quality standards necessary for harsh marine environments.

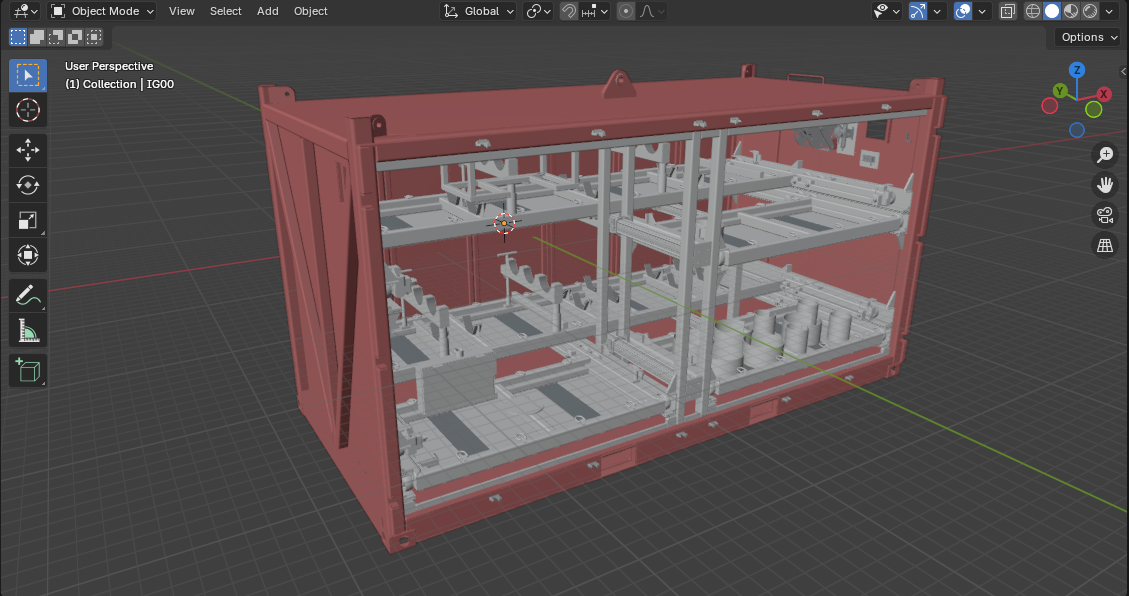

DNV-certified offshore containers encompass various designs including standard cargo containers, half-height containers, tank containers, and specialized units. Standard cargo containers typically measure 6.1 meters in length, 2.4 meters in width, and 2.4 meters in height, though dimensions can vary based on operational requirements. The structural framework consists of high-strength steel meeting DNV material grade requirements, typically with minimum yield strength of 355 N/mm² for primary structure members.

Cargo baskets represent a specialized category of offshore containers, characterized by their open-top design and removable sides. These units typically feature a steel-grid floor structure, integrated fork pockets, and pad eyes rated for specific lifting configurations. Common dimensions for cargo baskets range from 2.5 to 6.1 meters in length, with load ratings between 2 and 8 metric tonnes.

Structural Requirements

The primary structure of DNV-certified containers incorporates mandatory design elements including integrated four-point lifting arrangements, pad eyes manufactured from certified steel plates, and corner posts designed to withstand dynamic loading conditions. The framework must demonstrate compliance with impact resistance requirements, including drop testing from specified heights and load testing.

Material Specifications

Materials used in container construction must meet DNV standards for offshore use. Primary structural elements require certified steel grades with documented chemical composition and mechanical properties. Welding procedures must follow approved specifications, with all critical welds subject to non-destructive testing. Secondary materials, including floor decking and wall panels, must demonstrate suitable corrosion resistance and durability for marine environments.

Testing and Certification

DNV certification involves comprehensive testing protocols including prototype testing, production testing, and periodic inspections. Prototype testing encompasses proof load testing at 2.5 times rated capacity, two-point lifting tests, and impact testing. Production units undergo regular proof load testing at 1.5 times rated capacity and thorough visual inspections. Certification documentation must include detailed technical drawings, material certificates, and test reports.

Operational Requirements

Operational considerations for DNV-certified containers include maximum stack loading, seafastening arrangements, and periodic inspection schedules. Containers must display clear markings indicating maximum gross weight, tare weight, and payload capacity. Safety features include non-slip surfaces, drainage provisions, and secure closure mechanisms. Maintenance requirements specify annual inspections and testing, with detailed documentation of repairs and modifications.

Safety Features

Integral safety features include pad eye protection, fork pocket reinforcement, and impact-resistant corner structures. Containers must incorporate dedicated lashing points for cargo securing and provision for container stacking where applicable. Additional safety requirements address drainage systems, access arrangements, and visibility of safety markings.

Maintenance and Inspection

Regular maintenance procedures encompass structural inspections, wear point examination, and coating system verification. Critical areas requiring particular attention include lift point assemblies, corner posts, and floor structures. Inspection intervals follow DNV requirements with major surveys every 48 months and annual inspections for continued certification.

Conclusion

DNV-certified offshore containers and cargo baskets represent essential equipment for offshore operations, with certification ensuring compliance with stringent safety and quality standards. Understanding these requirements enables proper selection, maintenance, and operation of offshore container systems, contributing to safe and efficient offshore operations.