Offshore container engineering services play a crucial role in the oil and gas industry, providing robust and reliable solutions for the safe and efficient transportation, storage, and handling of equipment and materials in challenging marine environments. As a mechanical engineer, promoting these services involves highlighting the unique challenges faced by the industry and the innovative engineering solutions that address them.

The Critical Role of Offshore Containers in the Oil and Gas Industry

The oil and gas industry operates in some of the most demanding and hazardous environments on the planet. Offshore platforms, drilling rigs, and support vessels must contend with extreme weather conditions, corrosive seawater, and dynamic loads from wave action and wind. In this context, offshore containers are essential for protecting and transporting critical equipment and materials, ensuring the smooth operation of offshore activities.

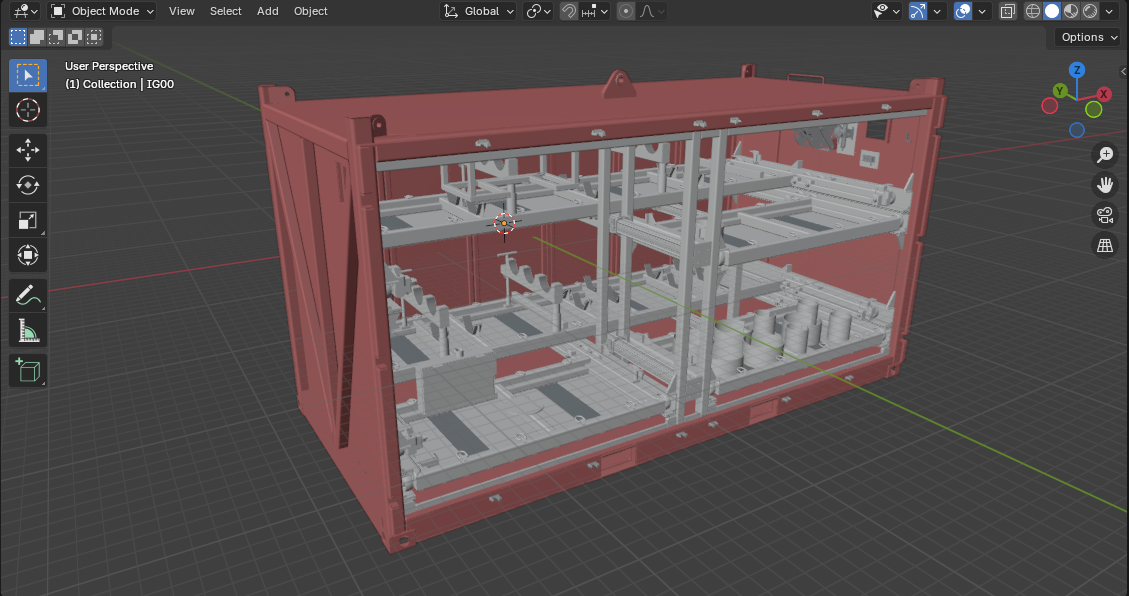

Offshore containers are designed to withstand the rigors of the marine environment, providing a secure and controlled space for sensitive equipment, hazardous materials, and valuable cargo. They are used for a wide range of applications, including the storage of drilling fluids, the transportation of machinery, and the housing of control systems and electronics. The engineering services behind these containers are vital for ensuring their performance, reliability, and safety in the challenging offshore conditions.

Addressing the Unique Challenges of the Offshore Environment

The offshore environment presents a host of unique challenges that require specialized engineering solutions. Corrosion, extreme temperatures, high humidity, and dynamic loads are just some of the factors that can impact the integrity and functionality of offshore containers. Mechanical engineers must address these challenges through innovative design, material selection, and manufacturing processes.

One of the primary challenges is corrosion, which can rapidly degrade materials in the presence of seawater and high humidity. Offshore container engineering services focus on selecting corrosion-resistant materials, such as stainless steel, aluminum alloys, and composite materials, to ensure the long-term durability of containers. Additionally, protective coatings and treatments are applied to further enhance corrosion resistance and extend the lifespan of the containers.

Dynamic loads from wave action, wind, and the movement of vessels also pose significant challenges. Offshore containers must be designed to withstand these loads without compromising their structural integrity. This involves the use of reinforced frames, bracing, and support members, as well as the application of finite element analysis (FEA) to optimize the design for strength and stability.

Key Benefits of Offshore Container Engineering Services

Offshore container engineering services offer a range of benefits that are tailored to the specific needs of the oil and gas industry. These benefits include enhanced safety, operational efficiency, cost savings, and regulatory compliance.

Safety is a paramount concern in the oil and gas industry, and offshore containers play a critical role in protecting personnel and equipment from hazards. Engineering services ensure that containers are designed to the highest safety standards, with robust structural integrity, secure sealing systems, and advanced monitoring technologies. This reduces the risk of accidents, spills, and equipment failures, promoting a safer working environment.

Operational efficiency is another key benefit of offshore container engineering services. Containers are designed to be easily handled, transported, and secured, minimizing downtime and maximizing productivity. The use of standardized designs, interlocking features, and compatible handling equipment enhances the efficiency of offshore operations, ensuring that containers can be quickly and safely moved into position.

Cost savings are achieved through the use of durable, low-maintenance materials and efficient manufacturing processes. Offshore container engineering services focus on delivering high-quality containers that require minimal maintenance and have a long service life, reducing the overall cost of ownership. Additionally, the use of modular and customizable designs allows for the reuse and repurposing of containers, further enhancing cost-effectiveness.

Regulatory compliance is essential in the oil and gas industry, and offshore container engineering services ensure that containers meet all relevant standards and regulations. This includes compliance with international maritime regulations, environmental standards, and industry-specific guidelines. Engineering services provide documentation, certification, and testing to verify that containers meet the required standards, ensuring legal and operational compliance.

Advanced Technologies and Methodologies

Offshore container engineering services leverage advanced technologies and methodologies to deliver innovative and effective solutions. These include the use of smart containers, advanced materials, and cutting-edge manufacturing techniques.

Smart containers are equipped with sensors, monitoring systems, and communication technologies that provide real-time data on the condition, contents, and environmental parameters of the container. This enables proactive maintenance, enhanced safety, and improved operational efficiency. The integration of Internet of Things (IoT) technology allows for remote monitoring and control, providing valuable insights and ensuring the optimal performance of the containers.

Advanced materials, such as high-strength steels, aluminum alloys, and composite materials, are used to enhance the durability, strength, and corrosion resistance of offshore containers. These materials offer excellent strength-to-weight ratios, reducing the overall weight of the containers while maintaining their structural integrity. The use of advanced manufacturing techniques, such as 3D printing and automated welding, further enhances the quality and precision of the containers.

Cutting-edge design and analysis tools, including finite element analysis (FEA) and computational fluid dynamics (CFD), are employed to optimize the performance of offshore containers. These tools allow mechanical engineers to simulate the behavior of containers under various load conditions, identify potential weaknesses, and refine the design for maximum strength and stability. The use of these advanced technologies ensures that offshore containers are engineered to the highest standards, providing reliable and efficient solutions for the oil and gas industry.

Customized Solutions for Specific Applications

Offshore container engineering services offer customized solutions tailored to the specific needs and applications of the oil and gas industry. This includes the design and manufacture of specialized containers for drilling fluids, machinery, control systems, and hazardous materials.

Drilling fluid containers are designed to safely store and transport drilling muds, chemicals, and other fluids used in offshore drilling operations. These containers are equipped with robust sealing systems, monitoring technologies, and protective coatings to prevent leaks and contamination, ensuring the safe and efficient handling of drilling fluids.

Machinery containers are engineered to protect and transport heavy equipment, such as pumps, compressors, and generators, used in offshore operations. These containers are designed with reinforced frames, secure mounting systems, and vibration damping features to minimize damage and ensure the safe transportation of machinery.

Control system containers house sensitive electronics and control equipment used in offshore operations. These containers are designed to provide a controlled environment, with temperature and humidity control, EMI shielding, and secure access systems to protect the equipment from environmental hazards and unauthorized access.

Hazardous material containers are engineered to safely store and transport hazardous substances, such as chemicals, fuels, and waste materials, used in offshore operations. These containers are designed with robust sealing systems, containment features, and monitoring technologies to prevent leaks and spills, ensuring the safe and compliant handling of hazardous materials.

Sustainability and Environmental Responsibility

Sustainability and environmental responsibility are increasingly important considerations in the oil and gas industry, and offshore container engineering services play a vital role in promoting these values. Engineering services focus on designing containers that minimize environmental impact, reduce waste, and enhance energy efficiency.

The use of recyclable materials, eco-friendly coatings, and efficient manufacturing processes reduces the environmental footprint of offshore containers. Engineering services also emphasize the design of containers that are easily disassembled and recycled at the end of their service life, promoting a circular economy and reducing waste.

Energy efficiency is enhanced through the use of lightweight materials, optimized designs, and advanced insulation technologies that reduce the energy required for transportation and operation. Additionally, the integration of renewable energy sources, such as solar panels and wind turbines, can further enhance the sustainability of offshore containers.