Offshore containers are critical components in the maritime and offshore industries, used for transporting goods, equipment, and supplies to offshore platforms, vessels, and other remote locations. Ensuring the safety and integrity of these containers is paramount to prevent accidents, environmental damage, and financial losses.

Structural Integrity

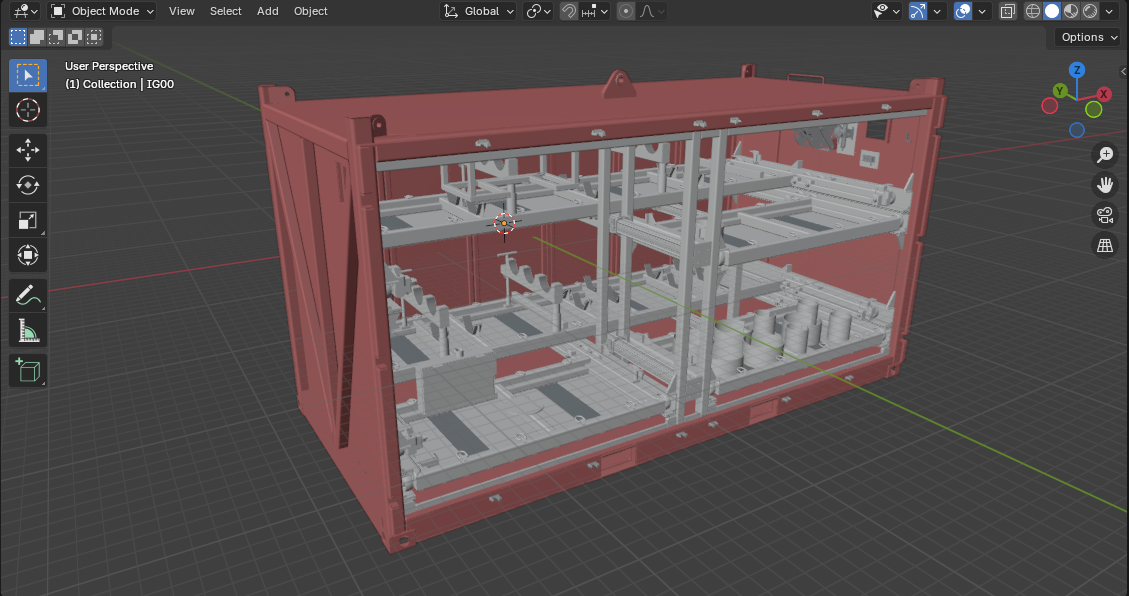

The structural integrity of offshore containers is crucial for their safe operation and longevity. Inspectors should begin by examining the container’s frame, ensuring that there are no signs of corrosion, cracks, or deformations. The corner castings, which are essential for lifting and securing the container, must be inspected for any damage or wear. The walls, roof, and floor of the container should be checked for dents, holes, or other forms of damage that could compromise the container’s strength.

Welds are another critical area to inspect. All welds should be continuous and free of defects such as porosity, undercuts, or incomplete penetration. The inspector should also verify that the container’s dimensions conform to the specified standards, as any deviations could affect its stacking and securing capabilities.

Safety Features

Safety features are essential for protecting both the container’s contents and the personnel handling it. The container’s doors must open and close smoothly, and the locking mechanisms should be in good working order. Safety latches and other securing devices should be present and functional. Inside the container, inspectors should check for the presence of safety labels and instructions, which provide important information on the container’s capacity, handling procedures, and emergency contacts.

Ventilation is another important safety feature, especially for containers used to transport hazardous materials. Inspectors should ensure that ventilation openings are not obstructed and that any ventilation systems are operational. For containers equipped with safety valves or pressure relief devices, these should be inspected to ensure they are in good condition and functioning correctly.

Regulatory Compliance

Offshore containers must comply with various regulations and standards set by international and national authorities. Inspectors should verify that the container has the necessary certifications and approvals, such as those issued by the International Maritime Organization (IMO) or the relevant classification societies. The container’s identification plate, which provides information on its manufacturer, serial number, and certification, should be present and legible.

Inspectors should also check that the container complies with the specific regulations of the region where it will be used. This may include additional safety features, environmental protections, or operational requirements. For containers used to transport dangerous goods, compliance with the International Maritime Dangerous Goods (IMDG) Code is essential. Inspectors should verify that the container is appropriately labeled and equipped for the specific types of dangerous goods it will carry.

Operational Readiness

Before an offshore container is put into service, it must be inspected to ensure it is operationally ready. This includes checking that all necessary equipment and accessories are present and in good condition. For example, lifting slings, shackles, and other rigging equipment should be inspected for wear or damage. The container’s interior should be clean and free of debris, and any internal fittings or securing points should be in good working order.

Inspectors should also verify that the container is properly prepared for its intended use. This may include checking that it is correctly loaded and secured, that any necessary documentation is in order, and that the container is ready for transport. For containers used in specific operations, such as drilling or production activities, additional checks may be required to ensure they meet the operational requirements.

Documentation and Record Keeping

Maintaining accurate and up-to-date documentation is a vital part of the inspection process. Inspectors should record the results of each inspection, including any defects or issues identified, and the actions taken to address them. This documentation provides a record of the container’s condition over time and helps to ensure that it remains safe and compliant.

Inspection records should include the date of the inspection, the name of the inspector, and a detailed description of the findings. Any repairs or maintenance carried out should also be documented, along with the dates and details of the work done. This information is essential for tracking the container’s history and for demonstrating compliance with regulatory requirements.

Conclusion

The inspection of offshore containers is a critical process that ensures their safety, integrity, and compliance with regulatory standards. By following a comprehensive inspection checklist that covers structural integrity, safety features, regulatory compliance, and operational readiness, inspectors can help to prevent accidents, protect the environment, and ensure the smooth operation of offshore activities. Regular and thorough inspections, combined with accurate documentation and record-keeping, are essential for maintaining the high standards required in the offshore industry.