Offshore containers are versatile units designed to meet the demanding requirements of offshore environments, particularly in the oil and gas industry. These containers are often modified to serve unique applications, ensuring they can withstand harsh conditions while meeting specific operational needs. The process of modifying offshore containers involves several considerations, including regulatory compliance, safety standards, and the unique risks associated with offshore operations.

Offshore containers are modified to serve a wide range of applications, from accommodation modules to specialized workshops and laboratories. Accommodation containers, for example, are designed to provide comfortable living quarters for offshore personnel. These containers are equipped with essential amenities, such as sleeping areas, bathrooms, and kitchen facilities, to ensure the well-being of the crew during extended offshore stays. The containers are built to ISO standard dimensions, allowing for quick installation on any offshore vessel and can be combined with other modules to create larger living spaces.

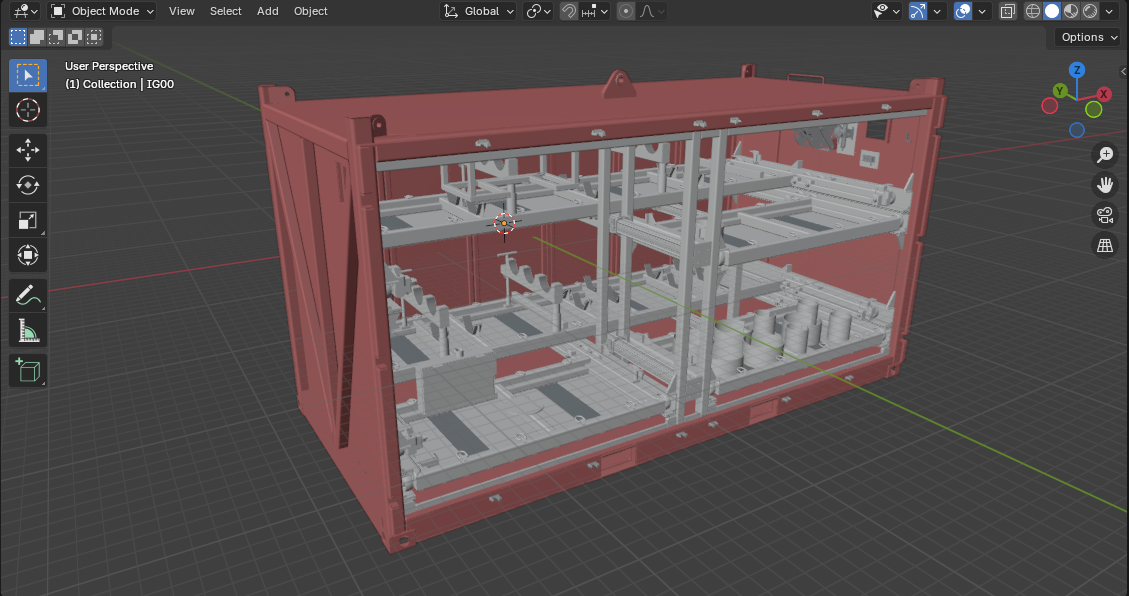

Workshop containers are another common modification, providing dedicated spaces for maintenance and repair operations. These containers are equipped with workbenches, tool storage, and power distribution systems, enabling technicians to perform essential tasks efficiently. The workshops are designed to be durable and safe, with features such as ventilation systems and lighting to enhance productivity and safety. Additionally, workshop containers can be customized with specific equipment, such as compressors and welding machines, to meet the unique requirements of offshore operations.

Laboratory containers are modified to support scientific research and analysis in offshore environments. These containers are equipped with specialized equipment, such as negative pressurization control systems, to maintain a safe and controlled environment for laboratory work. The laboratories are designed to meet A60 fire ratings, ensuring they can withstand the harsh conditions of offshore operations while providing a safe workspace for researchers.

In addition to these specialized applications, offshore containers are modified to support various other functions, such as waste management and storage. Waste management containers are designed to handle the disposal of wastewater and other waste materials generated during offshore operations. These containers are equipped with features such as sealed lids and drainage systems to prevent contamination and ensure safe disposal. Storage containers, on the other hand, are modified to provide secure and organized storage solutions for tools, spare parts, and other equipment. These containers can be equipped with shelves, racks, and insulation to protect the contents from the harsh offshore environment.

The modification process for offshore containers involves careful planning and execution to ensure compliance with industry standards and regulations. This includes the use of durable materials that can withstand corrosion, extreme temperatures, and harsh weather conditions. The containers are also designed to be compatible with standard lifting and transport systems, allowing for easy mobility and stacking on drilling rigs, ships, or other offshore installations.

Regular maintenance and inspection are crucial to ensure the continued reliability and safety of modified offshore containers. This includes checking for structural integrity, inspecting welds, and testing safety features to ensure they meet the required standards. By adhering to these maintenance practices, operators can reduce the risk of regulatory issues and penalties, contributing to overall operational efficiency.

In conclusion, offshore containers are modified to serve a wide range of unique applications in the offshore industry. From accommodation modules to specialized workshops and laboratories, these containers are designed to meet the demanding requirements of offshore environments while ensuring safety and compliance with industry standards. The modification process involves careful planning, execution, and regular maintenance to ensure the containers can withstand the harsh conditions and support the specific needs of offshore operations.