Heavy-duty offshore cargo baskets are indispensable tools in the oil and gas industry, particularly in drilling operations where the safe and efficient transportation of equipment, tools, and supplies is critical. These robust structures are designed to withstand the harsh and demanding conditions of the offshore environment, ensuring the integrity of the cargo and the safety of personnel. Heavy-duty cargo baskets are specifically engineered to handle large, bulky, and heavy items, such as drilling pipes, casings, and machinery, which are essential for the success of drilling operations.

Design and Functionality of Heavy-Duty Offshore Cargo Baskets

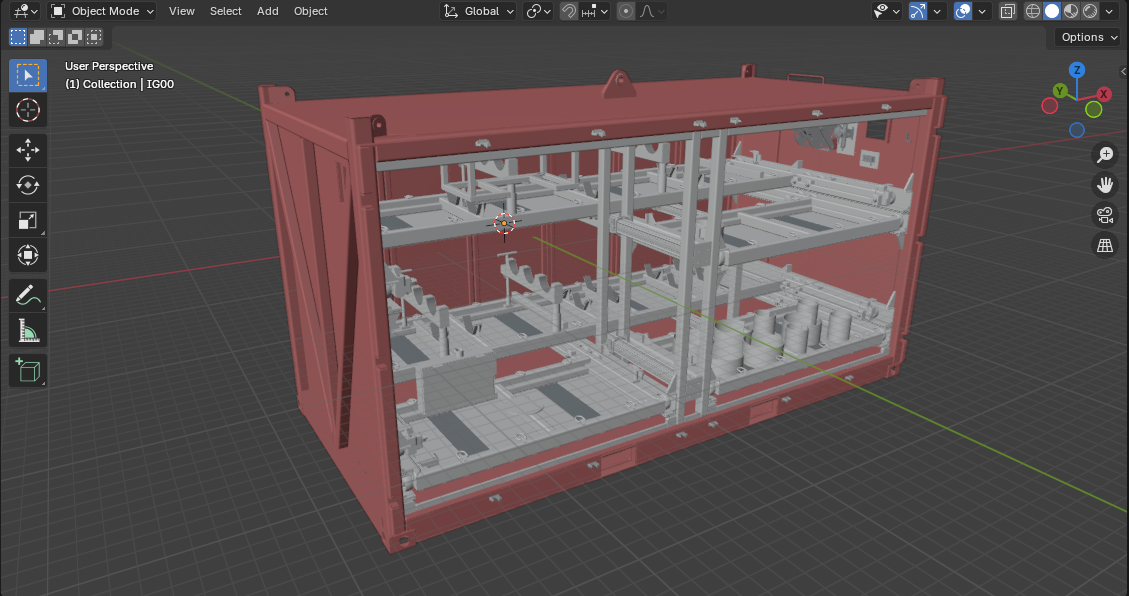

The design of heavy-duty offshore cargo baskets is driven by the need to transport large and heavy loads safely and efficiently in challenging offshore conditions. These baskets are typically constructed from high-strength steel or other durable materials that can withstand the corrosive effects of saltwater, extreme weather, and dynamic loads. The structural design is optimized to distribute weight evenly and prevent deformation or failure during lifting and transportation operations.

One of the key features of heavy-duty cargo baskets is their open-frame design, which allows for easy loading and unloading of bulky or irregularly shaped items. The baskets are equipped with reinforced floors, often made from steel grating or solid plates, to provide a stable base for the cargo. The sides of the baskets may be open or partially enclosed with mesh or solid panels to prevent items from shifting or falling out during transit. Lifting points, typically in the form of padeyes or lifting lugs, are strategically placed to ensure safe and balanced lifting using cranes or helicopters.

Safety is a paramount concern in the design of heavy-duty cargo baskets. These baskets are engineered to handle dynamic loads, such as those caused by wave action, wind, and the movement of the lifting equipment. Advanced simulation tools, such as finite element analysis (FEA), are often used to model the behavior of the baskets under various load conditions and optimize their design. Additionally, the baskets are equipped with safety features such as locking mechanisms and securing points to ensure that the cargo remains stable and secure during transportation.

Applications of Heavy-Duty Offshore Cargo Baskets

Heavy-duty offshore cargo baskets are widely used in drilling operations, where the transportation of large and heavy equipment is a routine requirement. One of the primary applications is the transport of drilling pipes and casings. These long and heavy items are essential for drilling operations, and their safe and efficient transport is critical to the success of the project. Heavy-duty cargo baskets are designed to accommodate the length and weight of these items, ensuring that they can be transported without damage or risk to personnel.

Another important application is the transport of drilling machinery and equipment. This includes items such as blowout preventers (BOPs), mud pumps, and drill bits, which are often large, heavy, and irregularly shaped. Heavy-duty cargo baskets provide a secure and stable platform for transporting these items, ensuring that they arrive at the drilling site in good condition and ready for use.

Heavy-duty cargo baskets are also used to transport bulk materials, such as cement, drilling mud, and spare parts. These materials are often required in large quantities and must be transported efficiently to avoid delays in drilling operations. The open-frame design of the baskets allows for easy loading and unloading, while the reinforced floors and securing points ensure that the materials remain stable during transit.

Engineering Considerations for Heavy-Duty Offshore Cargo Baskets

The engineering of heavy-duty offshore cargo baskets involves a range of specialized considerations to ensure their performance and reliability. One of the primary challenges is designing for dynamic loads. Offshore environments are characterized by wave action, wind, and the movement of lifting equipment, all of which can impose significant stresses on the cargo baskets. Engineers use advanced simulation tools, such as finite element analysis (FEA), to model the behavior of the baskets under various load conditions and optimize their design. This ensures that the baskets can withstand the dynamic forces encountered during lifting and transportation operations.

Another important consideration is corrosion resistance. Offshore environments are highly corrosive due to the presence of saltwater, which can degrade the structural integrity of the cargo baskets over time. To mitigate this risk, heavy-duty cargo baskets are constructed from corrosion-resistant materials, such as high-strength steel with protective coatings or stainless steel. Regular maintenance and inspections are also required to detect and address any signs of corrosion or wear.

Transportation and handling are additional engineering challenges. Heavy-duty cargo baskets must be designed for easy transport, often involving long journeys by sea or air. This requires careful consideration of weight, dimensions, and lifting points to ensure safe and efficient handling. Once on-site, the baskets must be capable of withstanding the rigors of repeated use, including loading, unloading, and lifting operations. This requires robust construction and the use of durable materials that can endure the stresses of the offshore environment.

Regulatory Compliance and Certification

Heavy-duty offshore cargo baskets must comply with a range of international standards and regulations to ensure their safety and reliability. These include standards set by organizations such as the International Organization for Standardization (ISO), the International Maritime Organization (IMO), and classification societies like Det Norske Veritas (DNV), the American Bureau of Shipping (ABS), and Lloyd’s Register. Compliance with these standards is verified through a rigorous certification process, which includes design review, material testing, and on-site inspections.

The certification process ensures that the cargo baskets meet the highest standards of safety and quality, providing assurance to operators and personnel alike. Regular inspections and maintenance are also required to maintain certification and ensure the ongoing safety and performance of the baskets throughout their service life.

Conclusion

Heavy-duty offshore cargo baskets are essential for the success of drilling operations in the oil and gas industry. Their design and engineering involve a high degree of customization and adherence to stringent safety standards, ensuring that they can withstand the harsh offshore environment and meet the specific needs of each project. By combining advanced engineering techniques with a focus on safety, reliability, and efficiency, heavy-duty cargo baskets play a critical role in enabling the safe and efficient transportation of equipment, tools, and supplies.