Driller cabins are critical control centers on offshore drilling platforms. They serve as the primary workspace for the driller, who is responsible for overseeing and controlling drilling operations. The driller cabin’s functionality is designed to enhance operational efficiency, improve safety, and optimize decision-making in the complex and high-stakes environment of offshore drilling.

Both driller cabins and local equipment rooms are essential components of offshore drilling operations, designed to maximize efficiency, safety, and control in the challenging marine environment.

Key features include:

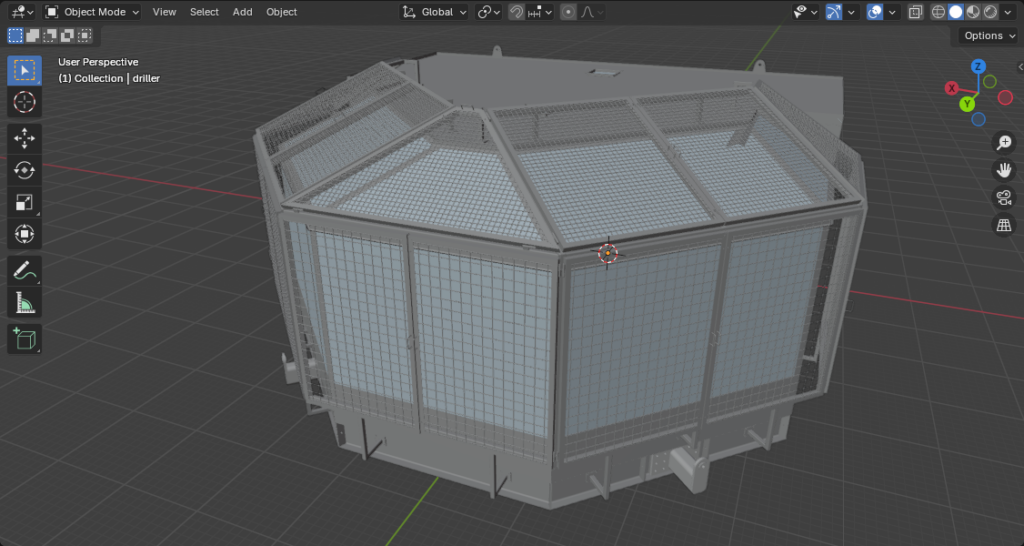

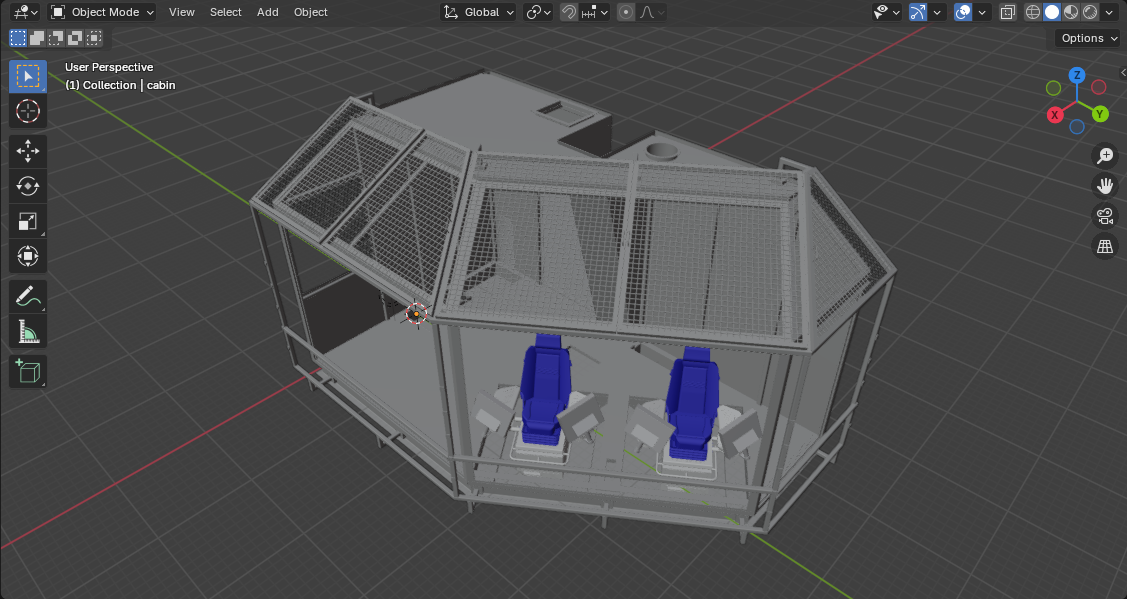

a) Ergonomic design: Optimized for long shifts and efficient operation, with adequate space for routine checks and repairs

b) Robust construction: Designed to withstand harsh offshore conditions

c) Fire and blast resistance (LERs): Enhanced safety features to protect critical equipment

d) ATEX compliance: Located at or by the drill floor in classified areas due to presence of explosive atmosphere

e) Climate control and ventilation systems: Maintained for comfort and equipment preservation, proper air circulation to prevent overheating of machinery and ensure pressurization, where appropriate

f) Noise reduction: Insulation to minimize external noise for improved concentration

We can provide the following engineering services associated with the design and installation of driller cabins and local equipment rooms.

- Feasibility Study and Concept Design:

- Rig-specific analysis for system integration

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

- Detailed Engineering Design:

- 3D modeling of the system layout

- Structural analysis for rig modifications

- Electrical system design and integration

- Insulation and fire rating

- Ventilation and pressurization

- ATEX classification and compliance

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Design of new foundations or support structures for equipment

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing rig systems

- Safety and Risk Engineering:

- Hazard and Operability (HAZOP) studies

- Failure Mode and Effects Analysis (FMEA)

- Safety Integrity Level (SIL) assessment

- Explosion risk assessment and zoning studies

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of operational procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design:

Please follow this link to download our brochure showcasing typical scopes of supply.