The supply chain is the backbone of any industry, and its efficiency directly impacts operational performance, customer satisfaction, and profitability. In today’s fast-paced and increasingly complex business environment, digital transformation has emerged as a critical enabler of supply chain optimization. For engineering consultancies, understanding and implementing digital transformation strategies in supply chain management is essential to help clients navigate challenges, improve resilience, and unlock new opportunities.

The Need for Digital Transformation in Supply Chain Management

Supply chains are becoming more intricate due to globalization, increasing customer expectations, and the growing complexity of products and services. Traditional supply chain management practices, often reliant on manual processes and siloed systems, are no longer sufficient to meet these demands. Disruptions such as the COVID-19 pandemic, geopolitical tensions, and climate change have further highlighted the vulnerabilities of conventional supply chains.

Digital transformation addresses these challenges by leveraging advanced technologies to create smarter, more agile, and resilient supply chains. It enables real-time visibility, data-driven decision-making, and seamless collaboration across the entire supply chain ecosystem. For engineering consultancies, helping clients adopt digital transformation strategies is a strategic imperative to enhance competitiveness and future-proof their operations.

Key Technologies Driving Digital Transformation in Supply Chains

Several digital technologies are at the core of transforming supply chain management. The Internet of Things (IoT) plays a pivotal role by connecting physical assets such as vehicles, warehouses, and equipment to the digital world. IoT sensors provide real-time data on location, condition, and performance, enabling companies to monitor and optimize their supply chains dynamically. For example, IoT-enabled tracking systems can provide end-to-end visibility of goods in transit, reducing delays and improving delivery accuracy.

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing supply chain operations by enabling predictive analytics and automation. AI algorithms can analyze vast amounts of data to forecast demand, optimize inventory levels, and identify potential disruptions before they occur. Machine learning models can also improve route optimization for logistics, reducing fuel consumption and transportation costs. These technologies empower companies to make proactive, data-driven decisions that enhance efficiency and reduce risks.

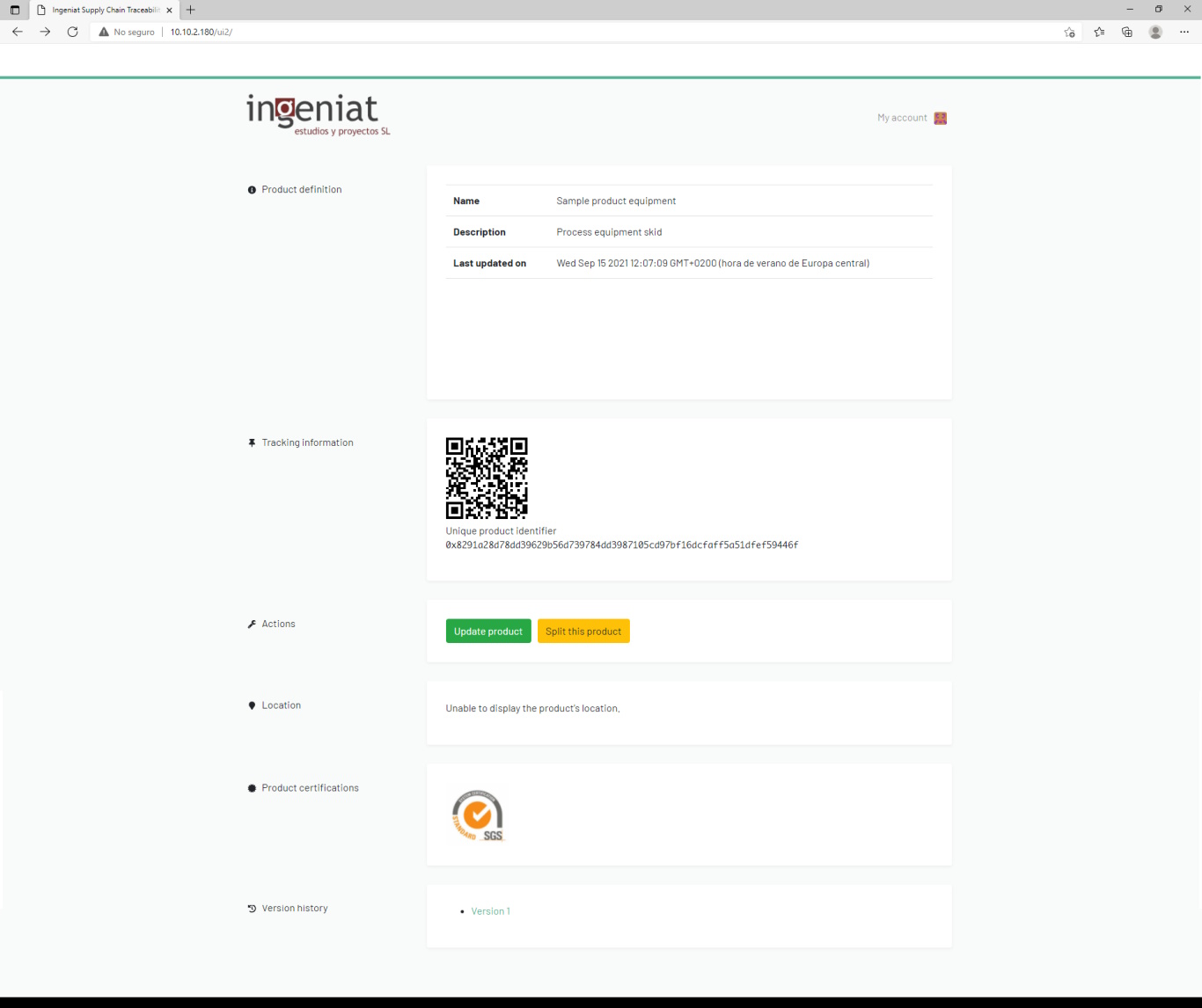

Blockchain technology is another game-changer for supply chain management. By providing a decentralized and immutable ledger, blockchain ensures transparency, traceability, and security in transactions. It enables stakeholders to track the movement of goods, verify authenticity, and reduce fraud. For industries such as pharmaceuticals and food, where traceability is critical, blockchain offers a robust solution to ensure compliance and build trust with customers.

Cloud computing is foundational to digital transformation, providing the infrastructure needed to store, process, and analyze large volumes of data. Cloud-based supply chain platforms enable real-time collaboration among stakeholders, regardless of their geographic location. They also support scalability, allowing companies to adapt quickly to changing market conditions.

Digital twins, virtual replicas of physical supply chain assets, are gaining traction as a tool for simulation and optimization. By creating a digital twin of a warehouse, factory, or logistics network, companies can test different scenarios, identify bottlenecks, and optimize processes without disrupting actual operations. This capability is particularly valuable for complex supply chains with multiple interdependencies.

Strategies for Implementing Digital Transformation in Supply Chains

Implementing digital transformation in supply chain management requires a strategic and holistic approach. The first step is to conduct a comprehensive assessment of the existing supply chain to identify pain points, inefficiencies, and opportunities for improvement. This assessment should involve all stakeholders, including suppliers, manufacturers, logistics providers, and customers, to ensure a complete understanding of the supply chain ecosystem.

Once the assessment is complete, the next step is to define clear objectives and key performance indicators (KPIs) for the digital transformation initiative. These objectives should align with the organization’s overall business goals, such as reducing costs, improving delivery times, or enhancing sustainability. KPIs provide a measurable way to track progress and evaluate the success of the transformation.

A phased implementation approach is often the most effective way to manage the complexity of digital transformation. Starting with pilot projects allows companies to test new technologies and processes on a smaller scale before rolling them out across the entire supply chain. For example, a company might begin by implementing IoT sensors in a single warehouse to monitor inventory levels and then expand the system to other locations based on the results.

Collaboration with technology partners and vendors is critical for successful digital transformation. Engineering consultancies can play a key role in helping clients select the right technologies, integrate them with existing systems, and provide ongoing support. Building strong partnerships with technology providers ensures access to the latest innovations and expertise.

Employee training and change management are equally important components of the transformation strategy. The adoption of new technologies often requires a shift in mindset and skills. Providing training programs and fostering a culture of innovation can help employees embrace digital tools and processes, ensuring a smooth transition.

Benefits of Digital Transformation in Supply Chain Management

The benefits of digital transformation in supply chain management are far-reaching. One of the most significant advantages is improved visibility and transparency. Real-time data from IoT sensors, AI analytics, and blockchain systems provide a clear view of the entire supply chain, enabling companies to identify and address issues quickly. This visibility enhances decision-making and reduces the risk of disruptions.

Operational efficiency is another major benefit. Automation of routine tasks, such as inventory management and order processing, reduces manual errors and frees up resources for more strategic activities. AI-driven demand forecasting and route optimization further enhance efficiency by ensuring that resources are used effectively.

Digital transformation also enhances supply chain resilience. By enabling companies to anticipate and respond to disruptions, digital technologies reduce the impact of unforeseen events such as natural disasters, geopolitical tensions, or supplier failures. For example, predictive analytics can identify potential risks in the supply chain and recommend mitigation strategies.

Sustainability is an increasingly important focus for supply chain management, and digital transformation plays a key role in achieving environmental goals. IoT and AI can optimize energy consumption, reduce waste, and minimize the carbon footprint of logistics operations. Blockchain technology ensures transparency in sourcing and production, enabling companies to meet regulatory requirements and consumer demands for sustainable practices.

Challenges and Considerations

While the benefits of digital transformation are compelling, the journey is not without challenges. One of the primary obstacles is the integration of new technologies with legacy systems. Many companies operate with outdated infrastructure that may not be compatible with modern digital solutions. Overcoming this challenge requires careful planning, investment in modernization, and collaboration with technology providers.

Data security and privacy are critical concerns in the digital transformation process. The increasing reliance on connected devices and data analytics exposes companies to cyber threats and data breaches. Implementing robust cybersecurity measures and ensuring compliance with data protection regulations are essential for safeguarding sensitive information.

The skills gap is another significant challenge. The successful adoption of digital technologies requires a workforce with expertise in data science, AI, IoT, and other emerging fields. Companies must invest in training and development programs to upskill their employees and attract top talent.

Cultural resistance to change can also hinder digital transformation efforts. Embracing new technologies often requires a shift in mindset and organizational culture. Leadership commitment, clear communication, and employee engagement are crucial for driving cultural change and ensuring the successful adoption of digital initiatives.

Conclusion

Digital transformation is reshaping supply chain management, offering unprecedented opportunities for efficiency, resilience, and sustainability. By leveraging technologies such as IoT, AI, blockchain, cloud computing, and digital twins, companies can optimize their supply chains and gain a competitive edge. However, the journey toward digital transformation is complex and requires careful planning, investment, and collaboration.