Custom-built offshore containers for the oil and gas industry are specialized units designed to meet the unique demands of offshore environments. These containers are essential for transporting equipment and supplies to and from offshore installations, ensuring the safety and efficiency of maritime operations.

Offshore containers are designed to withstand the harsh conditions of marine environments, including extreme weather, corrosive saltwater, and the rigors of marine lifting. They are constructed with durable materials and specific points for crane or helicopter lifting, making them suitable for repeated use in challenging offshore settings. These containers are often referred to as ‘DNV containers’ because they adhere to the DNV Standard for Certification no. 2.7-1, which ensures they are built to withstand the harsh and potentially hazardous environments encountered on oil rigs and ships. This standard is crucial for the safety and reliability of offshore operations, as it guarantees that the containers can handle the demanding conditions of offshore work.

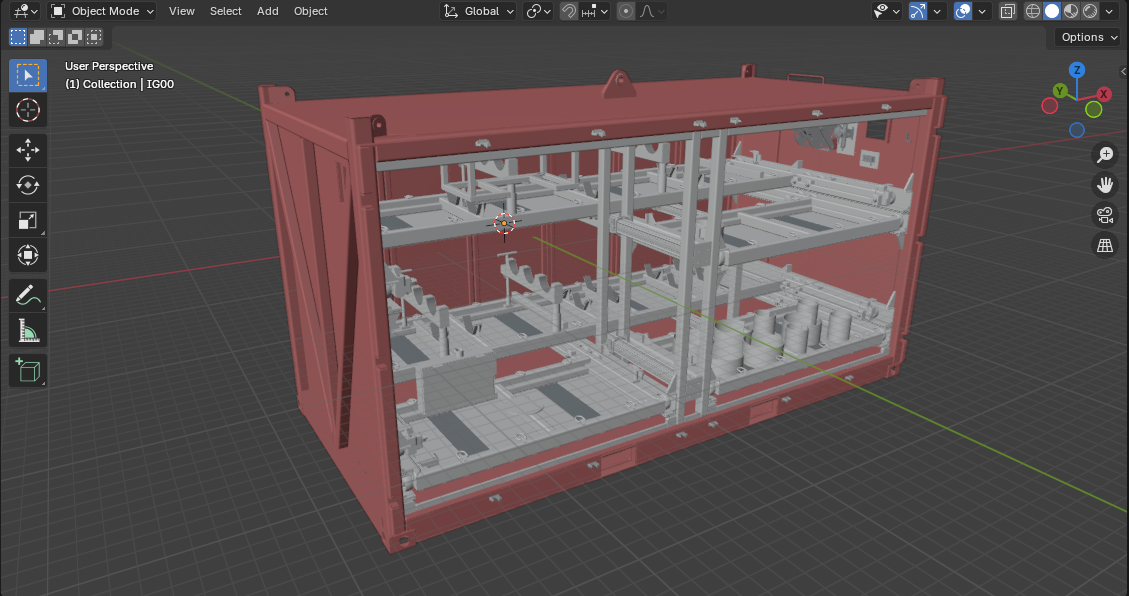

The design and construction of offshore containers are tailored to fit specific pieces of equipment, which means they often do not conform to the standard dimensions of ISO containers. This customization allows for the safe and efficient transport of specialized equipment, such as remotely operated vehicles (ROVs), control modules, and other critical systems used in offshore operations. High-specification control modules, including variable speed drive (VSD) and variable frequency drive (VFD) units, are also typically supplied for the oil and gas and offshore wind farm sectors. These modules are built to meet project-specific requirements, ensuring that they can house and protect critical systems and equipment effectively.

Offshore containers come in various forms, including cargo carrying units (CCUs) with double door options for flexible access, open-topped half heights for crane-loadable goods, and modified containers that can be customized to meet specific operational needs. These containers are used to transport and store goods, as well as to provide temporary installations such as laboratories, workshops, and accommodation modules.

The materials and construction techniques used in offshore containers are of the highest standards, with a particular focus on welding and non-destructive testing (NDT) to ensure the integrity and durability of the units. These containers are certified by classification societies to guarantee their compliance with international standards and regulations. The European Committee for Standardisation (CEN) defines three categories of offshore containers, each with specific requirements for design, materials, and construction.

In addition to their primary function of transporting equipment, offshore containers play a crucial role in reducing the environmental impact of offshore energy operations. They are used to safely transport offshore waste materials back onshore for processing, contributing to the sustainability of offshore activities.

The selection of an offshore container is a strategic decision that significantly impacts the success and safety of maritime operations. Professionals in the oil and gas sector must consider factors such as the container’s intended use, the specific equipment it will house, and the environmental conditions it will encounter. Custom-built offshore containers offer the flexibility and durability needed to meet these challenges, ensuring that offshore operations can be conducted safely and efficiently.

In conclusion, custom-built offshore containers for the oil and gas industry are specialized units designed to meet the unique demands of offshore environments. They are constructed to the highest standards, with a focus on durability, safety, and environmental responsibility. These containers play a crucial role in the transportation of equipment and supplies, as well as in providing temporary installations for offshore personnel. Their design and construction are tailored to fit specific operational needs, ensuring that they can withstand the harsh conditions of marine environments and contribute to the success of offshore operations.