The effective use of offshore containers and cargo baskets is critical to maintaining safety, efficiency, and compliance in offshore operations. These transportation units play a crucial role in moving equipment, tools, and materials between offshore installations and onshore bases. Ensuring their proper selection, handling, maintenance, and storage is essential to mitigating risks and enhancing operational continuity.

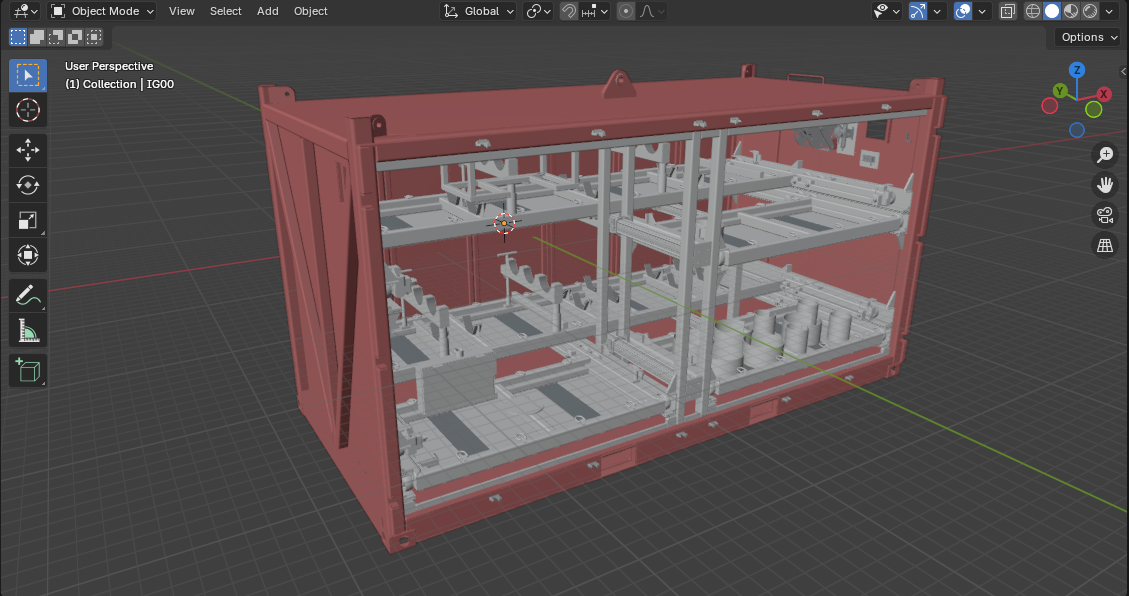

Offshore containers are specifically designed to withstand harsh marine environments, extreme weather conditions, and dynamic loads during lifting and transportation. Compliance with internationally recognized standards, such as those set by DNV 2.7-1, ISO 10855, and EN 12079, is necessary to ensure structural integrity and safety. The choice of containers must align with operational needs, considering factors such as payload capacity, material compatibility, and environmental exposure. Regular inspection, including thorough checks on lifting sets, structural components, and securing mechanisms, helps prevent accidents and ensures continued fitness for use.

Cargo baskets serve a similar function but are typically used for transporting irregularly shaped or oversized equipment that cannot be accommodated in standard containers. To maximize safety and efficiency, all items loaded into cargo baskets must be properly secured to prevent shifting during lifting and transit. The selection of appropriate securing methods, such as ratchet straps or chain lashings, contributes to load stability. Additionally, the use of certified lifting slings, shackles, and other rigging components guarantees compliance with operational safety requirements.

Handling offshore containers and cargo baskets requires adherence to established lifting and rigging procedures. Certified and competent personnel must oversee loading and offloading operations to ensure compliance with weight limits and proper weight distribution. Clear communication between crane operators, riggers, and deck crews is essential to minimize risks associated with suspended loads. The positioning of personnel must always account for potential hazards, including load swings, shifting weights, and sudden environmental changes such as wind gusts or vessel movement.

Regular maintenance and inspections are key to extending the service life of offshore containers and cargo baskets. Corrosion prevention measures, including appropriate coatings and periodic inspections, play a crucial role in preserving structural integrity. Any damaged units must be immediately removed from service, and repairs should be carried out by qualified professionals in accordance with regulatory standards. Documentation of inspections, maintenance activities, and repairs must be maintained to ensure traceability and compliance during audits.

Proper storage practices further contribute to the longevity and reliability of offshore containers and cargo baskets. Stacking arrangements should consider weight distribution and accessibility, with heavier units placed at the bottom and adequate spacing maintained to facilitate inspections and handling. Exposure to corrosive environments, such as saltwater spray, should be minimized through strategic placement and the use of protective coverings where necessary.

By implementing these best practices, offshore operations can achieve enhanced safety, efficiency, and regulatory compliance. The proper use, handling, and maintenance of offshore containers and cargo baskets not only protect personnel and assets but also contribute to the overall reliability and sustainability of offshore logistics.