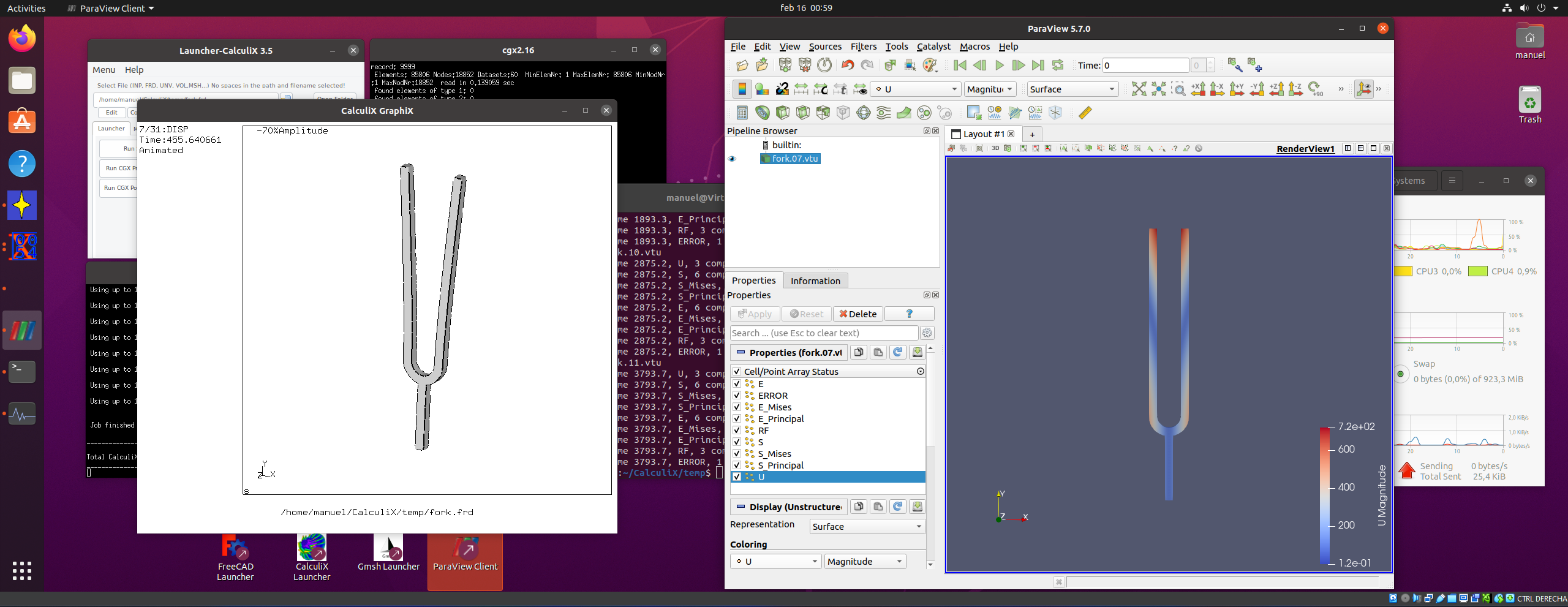

The main software package in our FEA workflow is CalculiX, an open source finite element analysis application with an implicit and explicit solver, developed by Dr. Guido Dhondt of MTU Aero Engines GmbH, with support from other figures in the academic world, such as Prof. Martin Kraska, Brandenburg University of Applied Sciences.

We are making available a pre-built Oracle VM VirtualBox appliance, ready to run and packed full with open source applications for engineering applications. This virtual appliance has been configured to meet the diverse needs of mechanical engineering professionals, providing a suite of tools that enhance productivity, streamline workflows, and deliver reliable results. The suite includes advanced analytics and postprocessing capabilities, allowing engineers to perform complex calculations and simulations with ease. This not only saves time but also ensures accuracy, reducing the risk of errors and rework.

The installed applications include, among others, CalculiX v2.20 (for FEA applications), OpenFOAM v9 (for CFD applications), ParaView v5.7.0, and FreeCAD v1.0, running on Ubuntu 20.04 LTS. Besides, a web-based interactive computing platform, Jupyter Notebook, is installed and configured for creating and sharing computational documents, allowing users to configure and deploy workflows in data science, scientific computing, and machine learning.