In the field of structural engineering, achieving cost efficiency without compromising safety, functionality, or durability is a constant challenge. Structural designs must balance technical excellence with economic viability, ensuring that projects meet performance requirements while staying within budget. Optimizing structural designs for cost efficiency requires a holistic approach that integrates innovative design strategies, advanced technologies, and sustainable practices.

Cost efficiency in structural engineering begins with a deep understanding of the project’s requirements, constraints, and objectives. Every project has unique parameters, such as load conditions, material availability, site-specific challenges, and client expectations. By thoroughly analyzing these factors, structural engineers can identify opportunities to optimize designs and reduce costs without sacrificing performance.

One of the most effective ways to achieve cost efficiency is through value engineering, a systematic process that evaluates design alternatives to deliver the best possible outcome at the lowest cost. Value engineering involves scrutinizing every aspect of the design, from material selection to construction methods, to identify areas where savings can be realized. This process requires collaboration among engineers, architects, contractors, and clients to ensure that cost-saving measures align with the project’s goals.

Leveraging Advanced Design Tools and Technologies

The use of advanced design tools and technologies is critical for optimizing structural designs. Building Information Modeling (BIM) is one such tool that has revolutionized the way structural engineers approach design. BIM enables the creation of detailed 3D models that integrate structural, architectural, and mechanical systems, allowing engineers to identify potential conflicts and inefficiencies early in the design process. By simulating different scenarios and analyzing the impact of design decisions, engineers can make informed choices that reduce material waste and construction costs.

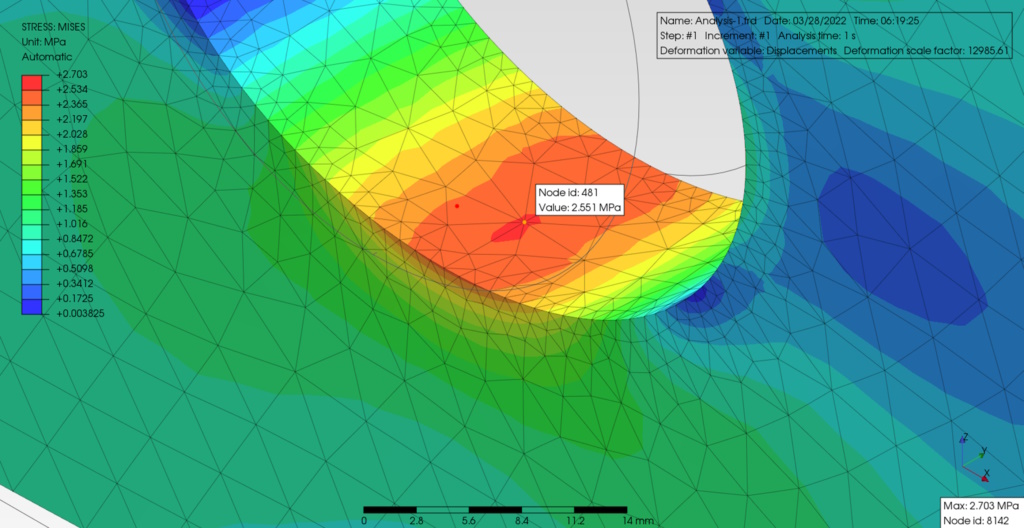

Finite Element Analysis (FEA) is another powerful tool that helps engineers optimize structural designs. FEA allows for the precise modeling of complex structures, enabling engineers to evaluate stress distribution, deformation, and failure modes under various load conditions. By identifying areas of over-design or under-utilization, FEA helps engineers refine their designs to use materials more efficiently, reducing costs without compromising safety.

Material Optimization and Selection

Material selection plays a crucial role in achieving cost efficiency. Structural engineers must carefully evaluate the properties, availability, and cost of different materials to determine the most economical and sustainable options. For example, high-strength materials such as advanced steel alloys or high-performance concrete can reduce the overall volume of material required, leading to cost savings in both material and construction.

Recycled and locally sourced materials are another avenue for cost optimization. Using recycled steel or concrete not only reduces material costs but also supports sustainability goals, which can be a key consideration for clients. Locally sourced materials minimize transportation costs and delays, further enhancing cost efficiency.

Prefabrication and modular construction techniques are also gaining traction as cost-effective solutions. By manufacturing structural components off-site and assembling them on-site, engineers can reduce construction time, labor costs, and material waste. Prefabrication also allows for greater precision and quality control, ensuring that components meet design specifications and performance requirements.

Streamlining Construction Processes

Optimizing structural designs for cost efficiency extends beyond the design phase to include construction processes. Collaboration between structural engineers and contractors is essential to ensure that designs are practical and cost-effective to build. Constructability reviews, where engineers and contractors evaluate the feasibility of construction methods, can identify potential challenges and opportunities for cost savings.

Standardization is another strategy that can streamline construction processes and reduce costs. By using standardized components and design details, engineers can simplify fabrication and assembly, reducing labor and material costs. Standardization also minimizes the risk of errors and rework, further enhancing cost efficiency.

Embracing Sustainable Design Practices

Sustainability and cost efficiency are increasingly intertwined in structural engineering. Sustainable design practices, such as energy-efficient systems, passive design strategies, and renewable materials, can reduce long-term operational costs and enhance the value of a structure. For example, incorporating natural ventilation and daylighting into a design can reduce energy consumption, lowering utility costs over the life of the building.

Life cycle cost analysis (LCCA) is a valuable tool for evaluating the long-term cost implications of design decisions. LCCA considers not only the initial construction costs but also the maintenance, operation, and disposal costs over the structure’s lifespan. By taking a holistic view of costs, engineers can make design choices that optimize both short-term and long-term cost efficiency.

Continuous Learning and Innovation

The field of structural engineering is constantly evolving, with new materials, technologies, and methodologies emerging regularly. To stay ahead, structural engineers must embrace a culture of continuous learning and innovation. Attending industry conferences, participating in professional development programs, and staying informed about the latest research and trends can provide engineers with the knowledge and skills needed to optimize designs for cost efficiency.

Collaboration with other disciplines, such as architecture, mechanical engineering, and environmental science, can also lead to innovative solutions that enhance cost efficiency. By working together, professionals from different fields can identify synergies and opportunities for optimization that might not be apparent when working in isolation.

Conclusion

Optimizing structural designs for cost efficiency is a multifaceted challenge that requires a combination of technical expertise, innovative thinking, and collaboration. By leveraging advanced design tools, carefully selecting materials, streamlining construction processes, and embracing sustainable practices, structural engineers can create designs that deliver exceptional value to clients and stakeholders. The key to success lies in balancing cost savings with performance, ensuring that structures are not only economical but also safe, durable, and functional. As the industry continues to evolve, structural engineers who prioritize cost efficiency will be well-positioned to lead the way in delivering high-quality, cost-effective solutions for the built environment.