Engineering solutions for offshore containers are critical for ensuring the safe and efficient transportation, storage, and handling of goods in the challenging marine environment. Mechanical engineers play a pivotal role in designing and implementing these solutions, which must withstand harsh conditions such as corrosion, extreme temperatures, and dynamic loads. This article explores the key engineering considerations and innovative solutions for offshore containers, focusing on structural integrity, material selection, environmental protection, and operational efficiency.

Understanding the Challenges of Offshore Environments

Offshore environments present unique challenges that require specialized engineering solutions. The corrosive nature of seawater, high humidity, and exposure to UV radiation can accelerate the degradation of materials. Additionally, offshore containers must endure dynamic loads from wave action, wind, and the movement of vessels. These factors necessitate robust and durable designs that can withstand the rigors of the marine environment while maintaining functionality and safety.

Mechanical engineers must begin by conducting a thorough analysis of the environmental conditions and operational requirements specific to the offshore location. This includes assessing the expected wave heights, wind speeds, temperature ranges, and the presence of corrosive agents. Understanding these factors allows engineers to design containers that are tailored to the specific challenges of the offshore environment.

Structural Integrity and Design

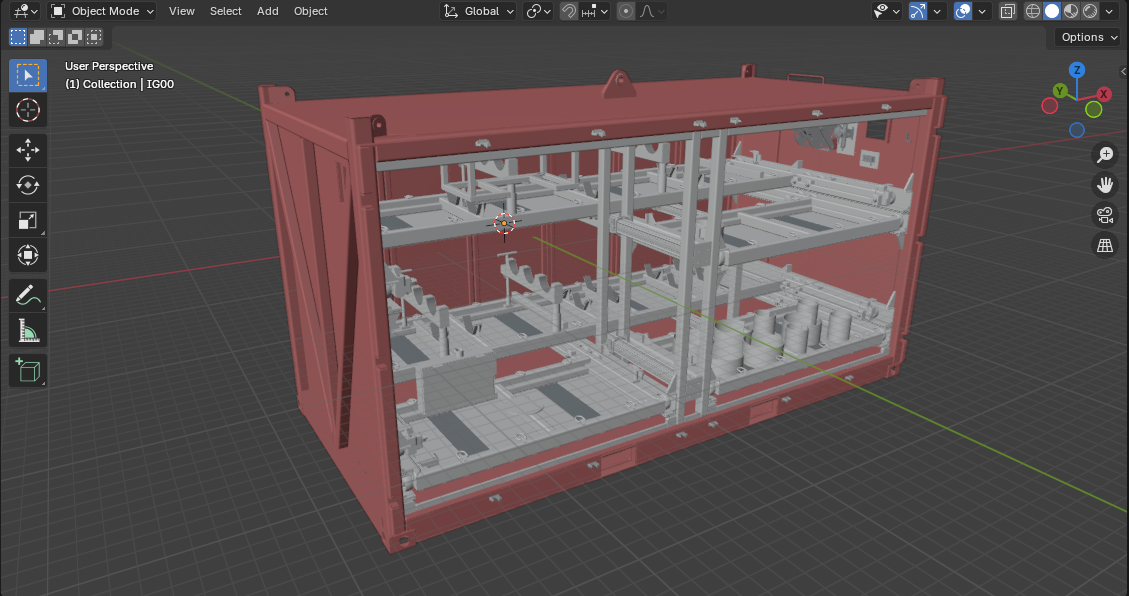

The structural integrity of offshore containers is paramount to their performance and safety. Mechanical engineers must design containers that can withstand the dynamic loads and stresses encountered in offshore operations. This involves selecting appropriate structural designs and materials that provide the necessary strength and durability.

One common approach is to use reinforced steel frames that provide a robust structure capable of resisting impact and dynamic loads. The frames are often designed with additional bracing and support members to enhance their strength and stability. Finite element analysis (FEA) is a valuable tool for engineers to simulate the behavior of the container under various load conditions and optimize the design for maximum strength and minimal weight.

In addition to the frame, the design of the container’s walls, roof, and floor must also be carefully considered. The use of corrugated or ribbed panels can enhance the structural integrity of these components by providing additional stiffness and resistance to deformation. The panels are typically made from high-strength materials such as steel or composite materials that offer excellent strength-to-weight ratios.

Material Selection and Corrosion Protection

Material selection is a critical aspect of designing offshore containers, as the materials must resist corrosion and maintain their structural integrity in the harsh marine environment. Mechanical engineers often opt for materials such as stainless steel, aluminum alloys, and composite materials that offer superior corrosion resistance and durability.

Stainless steel is a popular choice due to its excellent resistance to corrosion and high strength. However, it is important to select the appropriate grade of stainless steel that is suitable for the specific environmental conditions. For example, 316L stainless steel is commonly used in offshore applications due to its enhanced resistance to pitting corrosion in chloride-rich environments.

Aluminum alloys are another viable option, offering a good balance of strength, corrosion resistance, and lightweight properties. However, they may require additional protective coatings or anodizing to enhance their corrosion resistance in severe marine environments.

Composite materials, such as fiber-reinforced polymers (FRPs), are increasingly being used in offshore containers due to their exceptional strength-to-weight ratios and resistance to corrosion. FRPs can be tailored to provide specific mechanical properties and are not susceptible to corrosion, making them an attractive option for long-term use in offshore environments.

In addition to selecting corrosion-resistant materials, mechanical engineers must also implement protective coatings and treatments to further enhance the durability of offshore containers. This includes the application of epoxy coatings, zinc-rich primers, and other protective layers that create a barrier against corrosive agents. Regular inspection and maintenance of these coatings are essential to ensure their continued effectiveness.

Environmental Protection and Sustainability

Environmental protection and sustainability are increasingly important considerations in the design of offshore containers. Mechanical engineers must strive to minimize the environmental impact of these containers throughout their lifecycle, from manufacturing to disposal.

One key aspect of environmental protection is the prevention of contamination from the contents of the containers. This involves designing containers with robust sealing systems that prevent the leakage of hazardous materials into the marine environment. The use of double-walled containers with interstitial monitoring can provide an additional layer of protection by detecting and containing any leaks that may occur.

Sustainability considerations also extend to the materials and manufacturing processes used in the production of offshore containers. Engineers should aim to use recyclable materials and minimize waste during the manufacturing process. The adoption of eco-friendly coatings and treatments that have a lower environmental impact is also important.

Furthermore, the design of offshore containers should consider their end-of-life disposal. Engineers should strive to create containers that can be easily disassembled and recycled, reducing their environmental footprint. The use of modular designs and standardized components can facilitate the reuse and recycling of container materials.

Operational Efficiency and Handling

Operational efficiency is a crucial factor in the design of offshore containers, as they must be easily handled and transported in the dynamic offshore environment. Mechanical engineers must consider the logistical challenges of loading, unloading, and securing containers on vessels and offshore platforms.

One key consideration is the design of lifting points and securing mechanisms that facilitate the safe and efficient handling of containers. These features must be robust and easily accessible to ensure that containers can be quickly and securely moved into position. The use of standardized lifting points and securing mechanisms can enhance compatibility with various handling equipment and improve operational efficiency.

In addition to handling, the design of offshore containers must also consider their stackability and interoperability. Containers should be designed to be easily stacked and secured, maximizing the use of available space on vessels and platforms. The use of interlocking features and standardized dimensions can enhance the stability and efficiency of stacked containers.

Innovative Solutions and Technologies

Innovative solutions and technologies are continually being developed to enhance the performance and efficiency of offshore containers. Mechanical engineers must stay abreast of these advancements and integrate them into their designs to meet the evolving demands of the offshore industry.

One such innovation is the use of smart containers equipped with sensors and monitoring systems. These containers can provide real-time data on their condition, contents, and environmental parameters, enabling proactive maintenance and enhancing safety. The integration of Internet of Things (IoT) technology allows for remote monitoring and control, further improving operational efficiency.

Another emerging technology is the use of advanced composite materials and manufacturing techniques, such as 3D printing, to create customized and optimized container designs. These techniques enable the production of complex geometries and the integration of multiple functions into a single component, reducing weight and enhancing performance.

Conclusion

Engineering solutions for offshore containers require a comprehensive understanding of the unique challenges and requirements of the marine environment. Mechanical engineers play a vital role in designing containers that are structurally sound, corrosion-resistant, environmentally friendly, and operationally efficient. By leveraging advanced materials, innovative technologies, and robust design principles, engineers can create offshore containers that meet the demanding needs of the offshore industry while ensuring safety, sustainability, and operational excellence. The continuous evolution of engineering solutions in this field will drive further advancements, enhancing the reliability and efficiency of offshore operations in the years to come.