Offshore containers and cargo baskets are two essential tools in the offshore oil and gas industry, each serving distinct yet complementary roles in the transportation and storage of equipment, tools, and supplies. While both are designed to operate in the harsh and demanding conditions of the offshore environment, they differ significantly in their design, functionality, and applications. Understanding these differences is crucial for optimizing offshore operations, ensuring the safety of personnel, and maintaining the efficiency of logistics.

Design and Structural Characteristics

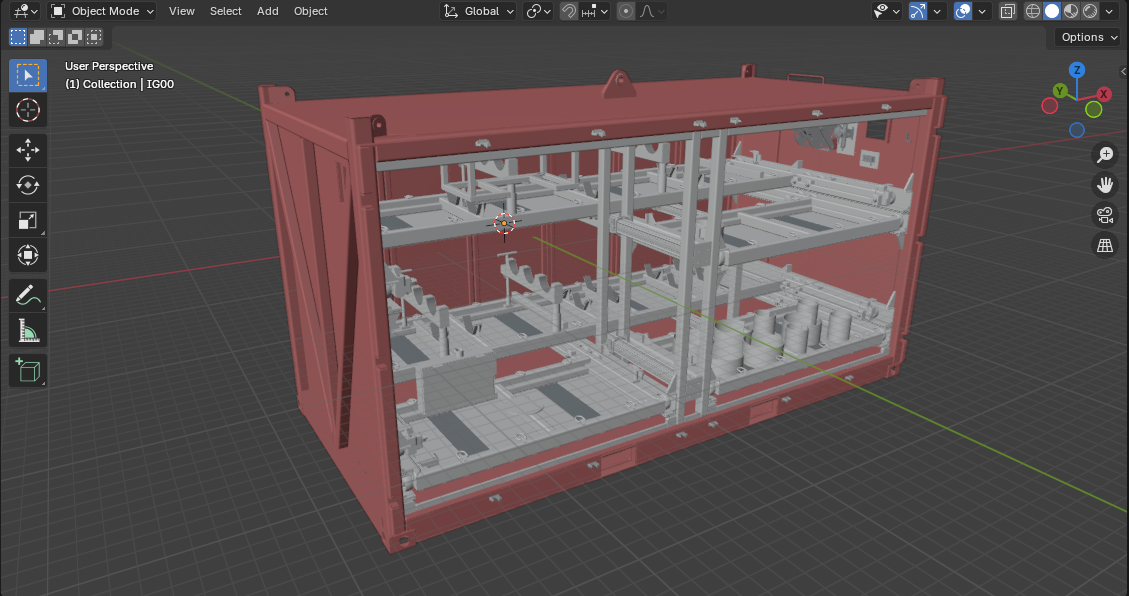

Offshore containers are fully enclosed structures designed to provide secure storage and transportation for a wide range of equipment and supplies. They are typically constructed from high-strength steel or other durable materials, with reinforced corners and lifting points to ensure safe handling during lifting operations. The enclosed design of offshore containers offers protection against environmental factors such as saltwater, wind, and rain, making them ideal for transporting sensitive or high-value items. The interior of the containers can be customized with shelving, racks, or partitions to organize and secure the cargo.

Cargo baskets, on the other hand, are open-frame structures designed for the transportation of bulkier or irregularly shaped items. They are constructed with robust frameworks and mesh or solid flooring to prevent cargo from shifting during transit. The open design of cargo baskets allows for easy loading and unloading of large or heavy items, such as drilling pipes, casings, and machinery. Lifting points are strategically placed to ensure balanced lifting using cranes or helicopters. Unlike containers, cargo baskets do not have walls or roofs, which makes them less suitable for protecting cargo from environmental elements.

Functionality and Applications

The functionality of offshore containers and cargo baskets is tailored to their respective designs and intended uses. Offshore containers are primarily used for the secure transportation and storage of equipment, tools, and supplies that require protection from the harsh offshore environment. They are commonly used to transport sensitive or high-value items, such as electronic equipment, instrumentation, and personal protective equipment (PPE). The enclosed design of the containers ensures that the cargo remains dry, clean, and secure, even in adverse weather conditions.

Cargo baskets, with their open-frame design, are ideal for transporting large, bulky, or irregularly shaped items that do not require protection from environmental elements. They are commonly used to transport drilling pipes, casings, and heavy machinery, as well as bulk materials such as cement and drilling mud. The open design allows for easy loading and unloading, making cargo baskets a practical choice for operations where quick access to the cargo is required.

Safety and Environmental Considerations

Safety is a paramount concern in the design and use of both offshore containers and cargo baskets. Offshore containers are equipped with advanced safety features, such as watertight seals, reinforced lifting points, and fire-resistant materials, to ensure the protection of the cargo and personnel. The enclosed design of the containers provides an additional layer of security, preventing cargo from shifting or falling out during transit. Containers used for hazardous goods may also include specialized safety features, such as flame arrestors, pressure relief valves, and chemical-resistant linings.

Cargo baskets, while lacking the enclosed protection of containers, are designed with safety in mind. They are constructed with robust frameworks and secure flooring to prevent cargo from shifting or falling out during lifting and transportation. The open design allows for easy inspection of the cargo, ensuring that it is properly secured before lifting. However, the lack of walls and roofs means that cargo baskets are less effective at protecting cargo from environmental elements, such as saltwater and rain.

Environmental considerations also play a role in the design and use of offshore containers and cargo baskets. Offshore containers, with their enclosed design, are better suited for transporting sensitive or hazardous materials that require protection from environmental contamination. They can be equipped with spill containment systems and chemical-resistant linings to prevent leaks and spills. Cargo baskets, while less effective at containing spills, are often used for transporting non-hazardous bulk materials that do not pose a significant environmental risk.

Regulatory Compliance and Certification

Both offshore containers and cargo baskets must comply with a range of international standards and regulations to ensure their safety and reliability. These include standards set by organizations such as the International Organization for Standardization (ISO), the International Maritime Organization (IMO), and classification societies like Det Norske Veritas (DNV), the American Bureau of Shipping (ABS), and Lloyd’s Register. Compliance with these standards is verified through a rigorous certification process, which includes design review, material testing, and on-site inspections.

For offshore containers, the certification process focuses on ensuring the structural integrity, safety features, and environmental protection capabilities of the container. Containers used for hazardous goods may require additional certifications to ensure compliance with specific regulations, such as the International Maritime Dangerous Goods (IMDG) Code.

Cargo baskets are certified based on their structural integrity, lifting points, and safety features. The certification process ensures that the baskets can withstand the dynamic loads and environmental conditions encountered during lifting and transportation operations. Regular inspections and maintenance are required to maintain certification and ensure the ongoing safety and performance of the baskets.

Conclusion

Offshore containers and cargo baskets are essential tools in the offshore oil and gas industry, each serving distinct yet complementary roles in the transportation and storage of equipment, tools, and supplies. Offshore containers, with their enclosed design, provide secure storage and transportation for sensitive or high-value items, offering protection from environmental elements and ensuring the safety of the cargo. Cargo baskets, with their open-frame design, are ideal for transporting large, bulky, or irregularly shaped items that do not require protection from environmental elements. Both types of equipment must comply with stringent international standards and regulations to ensure their safety and reliability.