The scope of work encompasses all aspects from pre-installation planning through final commissioning, with particular emphasis on safety, technical requirements, and operational efficiency.

Pre-Installation Planning and Engineering

Design Considerations

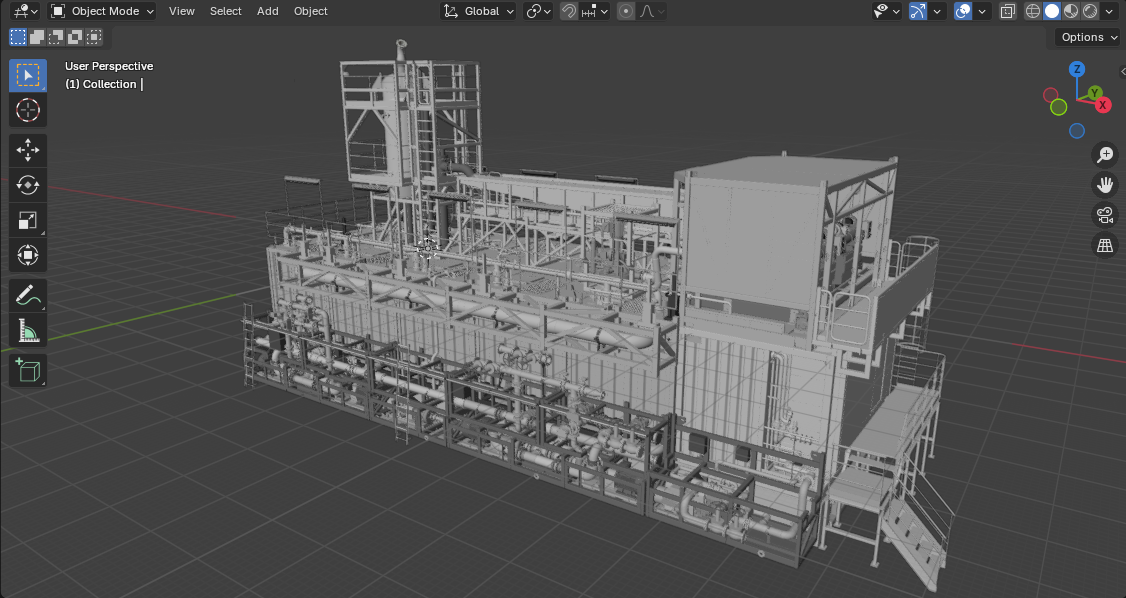

The installation of offshore modules begins well before any physical lifting operations. Engineering teams must conduct thorough structural analyses to verify the module support frame (MSF) capacity and its interface with the platform structure. Foundation preparations must account for dead loads, live loads, environmental loads, and dynamic responses. Integration of process and utility modules requires careful consideration of tie-in points, access requirements, and maintenance envelopes.

Transportation Engineering

Transportation engineering forms a critical component of module installation planning. Naval architects must evaluate vessel stability, sea-fastening requirements, and motion responses during transit. The selection of transportation vessels depends on module size, weight, and the intended installation method. Heavy lift vessels (HLV) specifications must be evaluated against module lifting requirements, including factors such as crane capacity, reach, and hook height.

Site Preparation

Platform Modifications

The existing platform structure typically requires modification to accept new modules. This includes strengthening of structural members, installation of additional bracing, and preparation of module support frames. Welding procedures must be carefully planned to manage hot work risks in potentially hazardous areas. Temporary support structures may be required during the installation phase.

Interface Management

Process and utility connections demand meticulous interface management. This encompasses electrical systems, instrumentation, piping, and control systems. Preparation includes the installation of temporary power supplies, lighting, and communication systems. Safety systems must remain operational throughout the installation process.

Installation Operations

Weather Planning

Installation operations are heavily dependent on environmental conditions. Weather forecasting and monitoring systems must be established with clear operational limits defined. Critical parameters include wind speed, wave height, current velocity, and visibility. The installation team must develop contingency plans for adverse weather conditions.

Lifting Operations

The actual lifting operation represents the most critical phase of module installation. The lift director must coordinate with all involved parties including crane operators, riggers, and safety personnel. The lifting sequence typically involves initial lift-off from the transportation vessel, transfer to the installation location, and final set-down on the module support frame. Tag lines and guide systems help control module movement during the lift.

Position Control

Precise positioning of modules is essential for successful integration. Survey teams establish control points and monitoring systems to guide final placement. Mechanical guidance systems, including pad-eyes and guides, facilitate accurate positioning. Tolerance management is critical for ensuring proper alignment of connection points.

Post-Installation Activities

Structural Connections

Once the module is positioned, permanent structural connections must be established. This includes welding of primary structural members, installation of mechanical fasteners, and completion of secondary steel works. Quality control measures include non-destructive testing (NDT) of critical connections and dimensional surveys.

System Integration

The integration of process and utility systems follows a predetermined sequence. This includes completion of piping tie-ins, electrical connections, and instrumentation hookups. Pressure testing of process systems and loop checking of control systems form essential parts of the commissioning process.

Safety and Risk Management

Personnel Safety

Safety considerations permeate all aspects of module installation. Personal protective equipment (PPE) requirements must be strictly enforced. Working at height presents particular challenges, requiring fall protection systems and proper access equipment. Confined space entry procedures may be necessary during tie-in operations.

Environmental Protection

Environmental protection measures must be implemented throughout the installation process. This includes provisions for spill prevention and response, waste management, and emissions control. Marine mammal observation may be required during certain operations.

Quality Assurance and Documentation

Quality Control

Quality control measures must be implemented at each stage of the installation process. This includes verification of dimensional tolerances, weld quality, and system integrity. Documentation requirements include as-built drawings, test reports, and certification records.

Commissioning Documentation

Comprehensive documentation packages must be prepared to support commissioning activities. This includes updated process and instrumentation diagrams (P&IDs), operating procedures, and maintenance manuals. Training requirements for operating personnel must be identified and addressed.

Conclusion

The successful installation of offshore process and utility modules requires careful planning, robust engineering, and meticulous execution. This report outlines the key considerations and methodologies required to ensure safe and efficient installation operations. Adherence to these guidelines, combined with proper risk management and quality control measures, will contribute to successful project outcomes.