Offshore containers are specialized transport units designed to withstand harsh marine environments and ensure the safe handling of cargo in offshore oil and gas operations. The classification society Det Norske Veritas (DNV) provides comprehensive standards and regulations governing the design, fabrication, testing, and certification of these containers. These standards, primarily outlined in DNV-ST-E271 and related guidelines, serve to enhance safety, structural integrity, and operational efficiency.

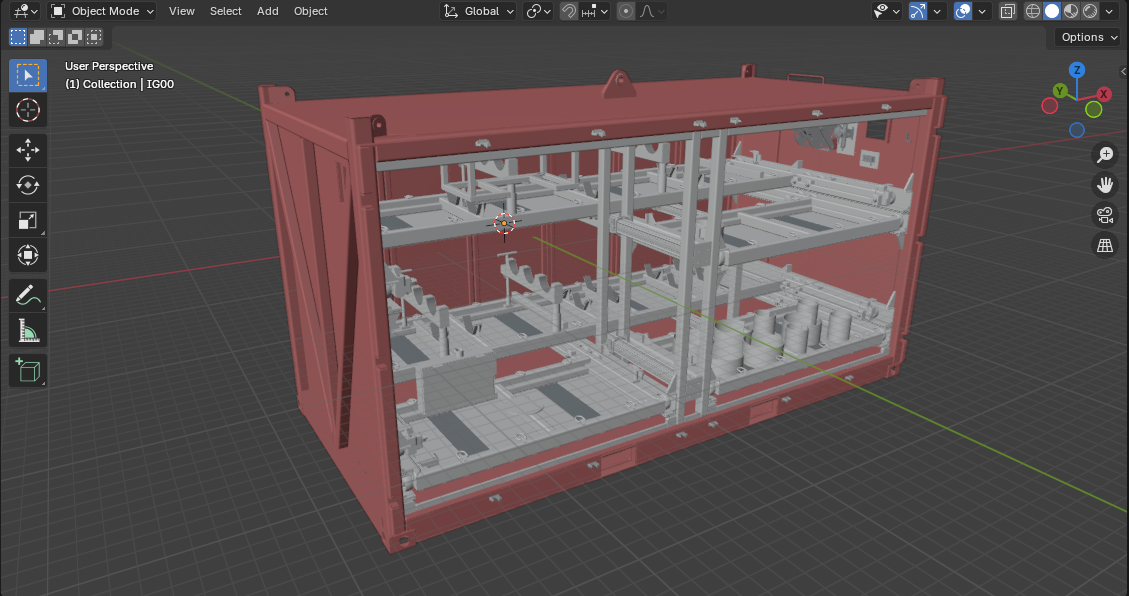

The core requirement for any offshore container under DNV regulations is the ability to endure dynamic lifting and operational loads that exceed those encountered in conventional shipping. To achieve this, DNV mandates stringent design principles, including the use of high-strength materials that resist corrosion, impact, and fatigue. The structural framework of offshore containers must be engineered to withstand forces exerted during lifting by cranes, handling in rough sea conditions, and potential accidental impacts. Additionally, each unit must feature lifting points that adhere to predefined strength criteria, ensuring secure and stable operations during hoisting and transfer between vessels and platforms.

Fabrication processes for offshore containers under DNV regulations must adhere to high-quality control standards, incorporating welding procedures that guarantee structural integrity. Manufacturers are required to follow approved welding techniques, with strict inspection regimes in place, including non-destructive testing methods such as ultrasonic and radiographic examinations. The application of corrosion-resistant coatings and appropriate surface treatments is another fundamental aspect to ensure longevity and reliability in marine environments.

Testing and certification form an essential component of the DNV regulatory framework. Each container undergoes a series of rigorous load tests, including vertical, horizontal, and impact tests, to confirm compliance with predefined safety parameters. Load-bearing structures must be subjected to proof load testing, typically exceeding the maximum operational weight, to validate the unit’s capacity. Additionally, drop tests simulate potential accidents, ensuring that the container remains structurally sound even under extreme conditions. The certification process also includes regular inspections and maintenance requirements, mandating periodic reassessment to confirm continued compliance with DNV standards over the operational life of the container.

Operational safety extends beyond the container’s design and construction. DNV standards require that offshore containers be equipped with proper identification markings, including weight specifications, maximum payload capacity, and identification numbers for tracking and compliance verification. Furthermore, guidelines dictate that all lifting equipment associated with these containers, such as slings and shackles, meet specific safety criteria and are regularly inspected for wear and tear.

In addition to DNV-ST-E271, other relevant standards such as DNV-ST-E273 for portable offshore units provide additional specifications for more specialized transport and storage containers. Compliance with these regulations is vital for ensuring safety in offshore logistics and transportation operations. The continuous evolution of DNV standards, driven by advancements in engineering practices and lessons learned from offshore incidents, ensures that offshore containers remain fit for purpose, providing robust and reliable solutions for the industry’s demanding requirements.