Thermal hydrolysis technology (THT) is an advanced waste treatment process that is increasingly being adopted onboard marine vessels to manage organic waste and sludge effectively. This technology enhances biodegradability and facilitates subsequent treatment processes, ensuring compliance with international marine pollution regulations such as MARPOL Annex IV and V.

THT is a high-temperature, high-pressure pre-treatment process that breaks down organic materials such as food waste, sewage sludge, and other biodegradable residues. The process subjects the waste to temperatures typically between 160°C and 180°C and pressures around 6–8 bar for a short duration (usually 20–30 minutes). This thermal and mechanical action disrupts the cellular structure of the organic material, making it more accessible for microbial degradation.

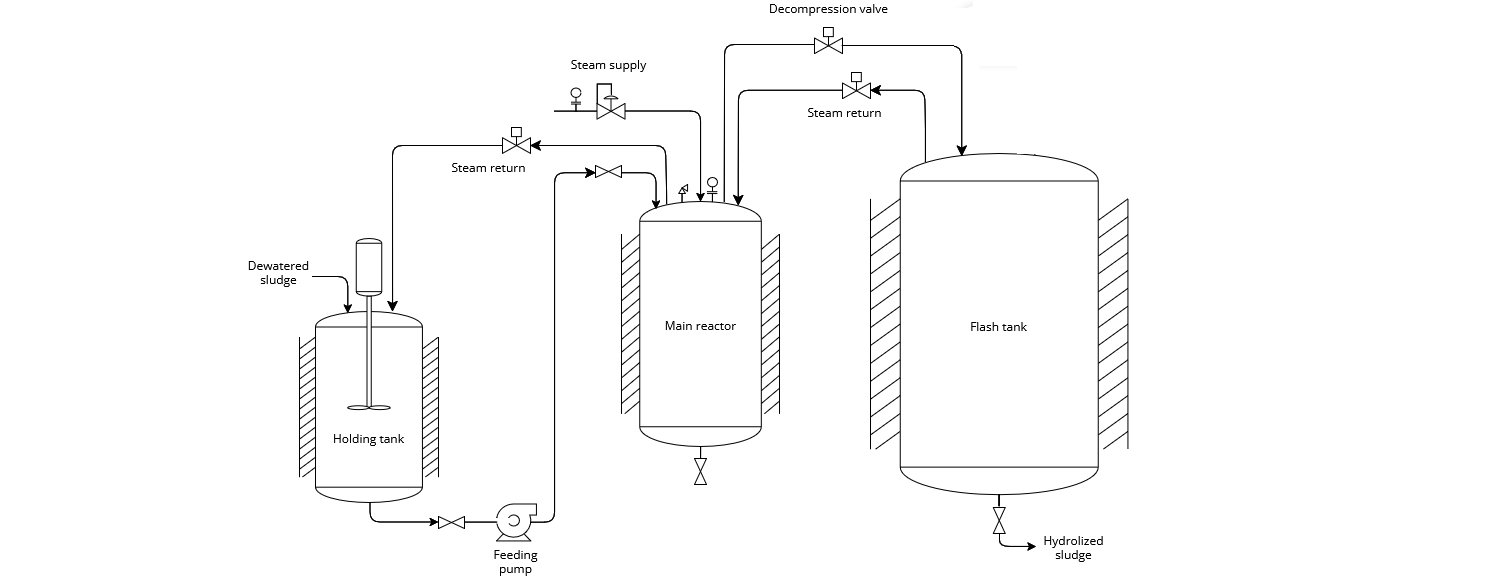

The operation of THT onboard marine vessels involves several key steps:

- Waste Collection and Pre-Treatment (Preheated or Holding Tank)

- Organic waste, including sewage sludge and food scraps, is collected and transferred to a holding tank, preferably with mixing and heating capabilities.

- The waste may undergo initial maceration and dewatering to reduce particle size and improve the efficiency of the hydrolysis process.

- Thermal Hydrolysis Process (Main Reactor)

- The waste is pumped into a hydrolysis reactor.

- Steam is introduced to elevate the temperature and pressure within the reactor.

- The waste is held under these conditions for a controlled duration to ensure adequate breakdown of organic structures.

- Depressurization and Cooling (Flash Tank)

- The reactor undergoes a controlled depressurization process, causing the waste to undergo rapid expansion.

- This step further enhances cell disruption, increasing biodegradability.

- Post-Treatment and Disposal (Digester)

- The hydrolyzed waste is transferred to a biological treatment system, such as an anaerobic digester or an advanced wastewater treatment plant.

- Enhanced biodegradability improves digestion efficiency, leading to better biogas production if anaerobic digestion is employed.

- Final effluent is treated to meet environmental discharge regulations before being released overboard or stored for disposal at port facilities.

This technology provides a number of advantages, including:

- Improved Waste Reduction: Enhances breakdown of organic material, reducing the overall volume of waste.

- Increased Biogas Yield: Facilitates biogas production when integrated with anaerobic digestion, providing a renewable energy source onboard.

- Enhanced Compliance: Helps vessels meet stringent environmental regulations by improving wastewater treatment efficiency.

- Energy Efficiency: Reduces the energy and chemical requirements of downstream treatment processes.

- Odor and Pathogen Reduction: Effectively neutralizes pathogens and minimizes odor, improving onboard hygiene and safety.

We can provide the following engineering services associated with the design and installation of a thermal hydrolysis system suitable for treatment of wastewater.

- Feasibility Study and Concept Design:

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

- Detailed Engineering Design:

- Process engineering and equipment sizing

- Piping and Instrumentation Diagrams (P&IDs)

- 3D modeling of the equipment layout

- Electrical system design and integration

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing ship systems (e.g., power, water)

- Modification of existing piping systems

- Safety and Risk Engineering:

- Failure Mode and Effects Analysis (FMEA)

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Analysis of the collection system’s environmental benefits

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design: