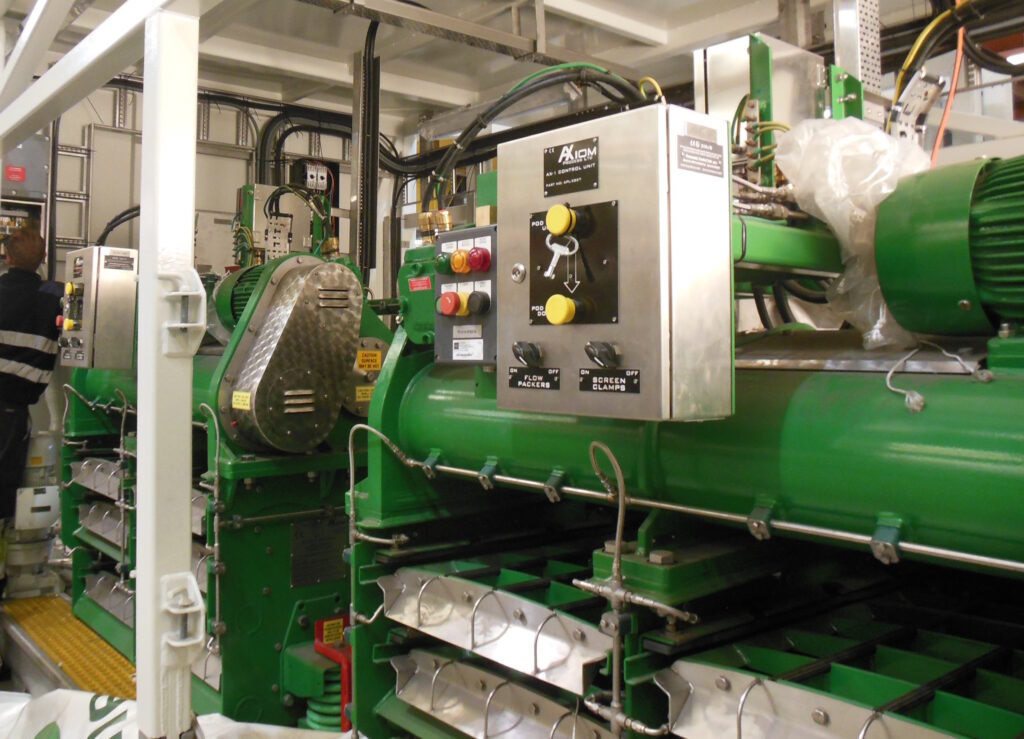

Offshore drilling equipment skids are modular, self-contained platforms or frames designed to house and transport specific drilling equipment and systems. These skids are essential in offshore drilling operations, as they enable the deployment, operation, and maintenance of various drilling tools and machinery in challenging marine environments.

Equipment skids facilitate the easy transportation and installation of heavy or specialized equipment on offshore platforms or vessels, enabling the integration of various subsystems and equipment into the offshore drilling operation and providing flexibility in the setup, replacement, or addition of skids based on operational needs.

We can provide the following engineering services associated with the design and installation of an equipment skid or module suitable for offshore operation.

- Feasibility Study and Concept Design:

- Rig-specific analysis for system integration

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

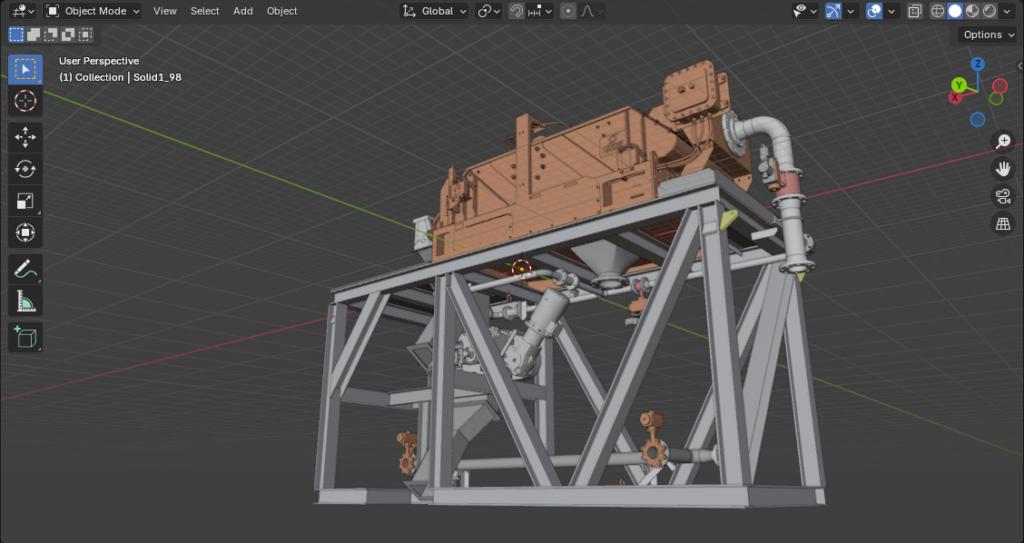

- Detailed Engineering Design:

- Process engineering and equipment sizing

- Piping and Instrumentation Diagrams (P&IDs)

- 3D modeling of the system layout

- Structural analysis for rig modifications

- Electrical system design and integration

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Design of new foundations or support structures for equipment

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing rig systems

- Modification of existing piping systems

- Safety and Risk Engineering:

- Hazard and Operability (HAZOP) studies

- Failure Mode and Effects Analysis (FMEA)

- Safety Integrity Level (SIL) assessment

- Explosion risk assessment and zoning studies

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of operational procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design:

Please follow this link to download our brochure showcasing typical scopes of supply.