A drilling mud cooling system or mud cooler is a critical piece of equipment in offshore drilling operations, designed to maintain optimal temperature of the drilling fluid (mud) circulating through the wellbore.

The drilling mud cooling system plays a crucial role in maintaining the efficiency, safety, and cost-effectiveness of offshore drilling operations by precisely controlling the temperature of the drilling fluid.

Broadly speaking, the most significant highlights of this type of cooling system are as follows:

A) Functionality:

- Heat Removal and Mud Property Preservation: Extracts excess heat generated by friction in the wellbore and surface equipment. Maintains mud temperature within an optimal range (typically 50-60°C). Prevents degradation of mud properties due to overheating.

- Improved Drilling Efficiency: Optimizes mud properties for better drilling performance.

- Extended Equipment Life: Reduces thermal stress on drilling equipment.

- Enhanced Safety: Minimizes risks associated with overheated mud.

- Cost Reduction: Lowers mud replacement and treatment costs.

- Equipment Protection: Safeguards downhole tools and surface equipment from thermal damage.

- Wellbore Stability: Helps maintain wellbore stability by controlling mud temperature.

- Designed for seamless integration with existing mud circulation systems.

- Includes standardized connections for easy installation and replacement.

- May feature remote monitoring capabilities for integration with rig control systems.

- Engineered for space efficiency to minimize footprint on offshore platforms.

- May be vertically oriented to save deck space.

- Seawater: Readily available and cost-effective, but can lead to increased corrosion and fouling.

- Closed-loop glycol: Offers better temperature control and reduces corrosion issues, but requires additional equipment.

- Self-cleaning mechanisms (e.g., reversible flow or backwash)

- Chemical injection points for anti-fouling treatments

- Easy-access designs for manual cleaning during maintenance

We can provide the following engineering services associated with the design and installation of a modular drilling mud cooling system.

- Feasibility Study and Concept Design:

- Rig-specific analysis for system integration

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

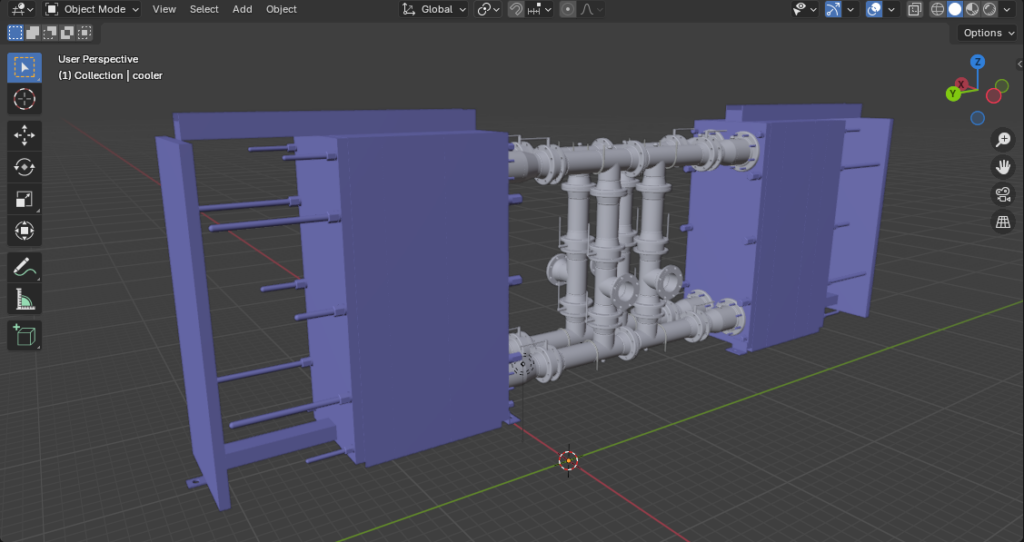

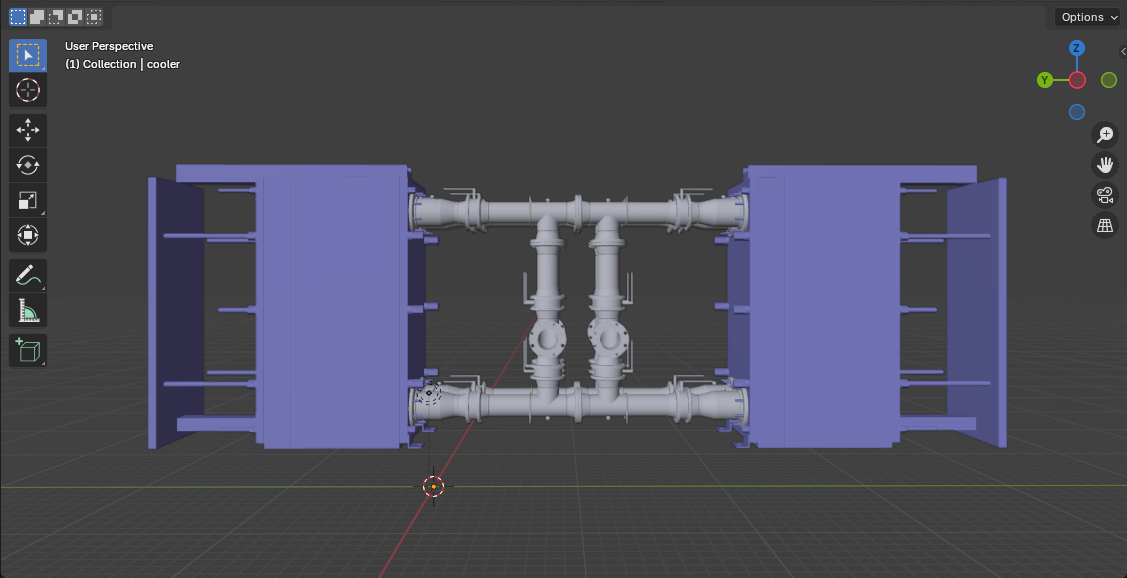

- Detailed Engineering Design:

- Process engineering and equipment sizing

- Piping and Instrumentation Diagrams (P&IDs)

- 3D modeling of the system layout

- Structural analysis for rig modifications

- Electrical system design and integration

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Design of new foundations or support structures for equipment

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing rig systems

- Modification of existing piping systems

- Safety and Risk Engineering:

- Hazard and Operability (HAZOP) studies

- Failure Mode and Effects Analysis (FMEA)

- Safety Integrity Level (SIL) assessment

- Explosion risk assessment and zoning studies

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of operational procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design:

Please follow this link to download our brochure showcasing typical scopes of supply.