Offshore containers are specialized units designed for use in marine environments, particularly on offshore platforms, drilling rigs, and ships. Their primary purpose is to safely transport equipment, supplies, and materials in harsh sea conditions.

Here are the key characteristics and functionalities:

- Robust construction:

- Made of high-strength steel to withstand extreme weather and sea conditions

- Reinforced corners and lifting points to handle heavy loads and repeated lifting operations

- Standardized design:

- Typically conform to DNV 2.7-1, EN 12079, or ISO 10855 standards

- Standardized dimensions for easy stacking and efficient use of deck space

- Weatherproof:

- Sealed against water ingress to protect contents from seawater and moisture

- Often equipped with drainage holes to prevent water accumulation

- Lifting and handling features:

- Four-point lifting arrangement for balanced and secure hoisting

- Designed for safe handling by cranes and forklifts

- Secure cargo containment:

- Internal tie-down points to secure cargo during transport

- Lockable doors to prevent unauthorized access and theft

- Versatility:

- Available in various types such as general purpose containers, tank containers, and special purpose units (e.g., for chemicals or waste)

- Can be customized for specific offshore operations or equipment

- Safety features:

- High visibility markings for easy identification during operations

- Often equipped with safety nets or removable rails to prevent falling objects

- Corrosion resistance:

- Protective coatings or materials to withstand the corrosive marine environment

- Stackability:

- Designed to be safely stacked, often up to 3 units high, to maximize deck space utilization

- Documentation and certification:

- Each container typically has a unique identification number and certificate

- Regular inspections and recertification to ensure ongoing compliance with safety standards

Our bespoke designs typically address the following requirements:

- Compliant with DNV Standard for Certification No. 2.7-1 Offshore Containers and No. 2.7-2 Service Containers.

- High tensile carbon steel design, coating system compliant with Norsok M-501 and ISO 12944.

- Standard design suitable for design temperature of -20ºC, lower temperature (-40ºC) as option.

- Forklift pockets and certified lifting lugs and lifting set.

- Stackable up to two heights without requiring to detach the lifting slings.

- Internal tie down points for secure cargo fastening.

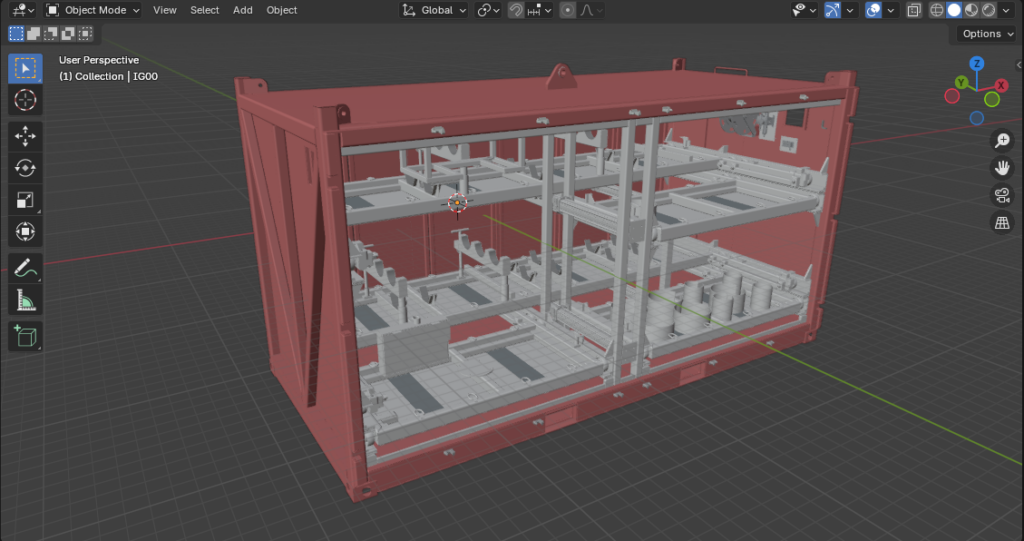

- Custom designs for special cargo or load configurations, and stable lifting arrangements.

- Custom designs including shelves, intermediate decks, workbenches, overhead / cranes, etc.

- Other dimensions and ratings upon request.

- Optional design compliant with DNV’s Standard for Certification No 2.7-3 for extended ratings up to 50 tons.

These characteristics enable offshore containers to efficiently and safely transport various materials and equipment in challenging offshore environments, supporting the complex logistics of offshore operations.

Other types of configurations can be identically considered, including the design of A60 rated modules compliant with DNV 2.7-2 and Norsok Z-015, including fire protection engineering, ventilation and pressurization, and installation of equipment suitable for hazardous areas

Please follow this link to download our brochure showcasing typical scopes of supply, or read this article for further information on the certification proces..