Vacuum-based waste collection systems are used onboard ships to efficiently manage and transport sewage and other wastewater to treatment facilities. It is recognized as a highly efficient and environmentally friendly solution for managing different types of residues onboard ships. By using vacuum pressure to transport waste, this system offers significant advantages in terms of water efficiency, installation flexibility, and environmental compliance.

The vacuum-based waste collection system is designed to collect food residue or equivalent waste residue, and transport it to a centralized holding tank or treatment system. The key feature of this system is the use of vacuum pressure to move waste through the pipelines, as opposed to relying on gravity flow, which is common in traditional waste systems.

The vacuum-based waste collection system operates by creating a vacuum in the piping network. When a valve is opened at the collection point, the differential pressure between the vacuum inside the pipes and the ambient air pressure outside the system causes the waste to be rapidly sucked into the pipes and transported to the collection tank.

This system allows for flexible pipe routing, enabling waste collection points to be located far from the collection tank or in areas below the waterline, where gravity-based systems would struggle. Additionally, the reduced water usage per flush significantly decreases the volume of wastewater generated, easing the load on the sewage treatment facilities.

The key components of a vacuum-based waste collection system are as follows:

A. Vacuum Pumps:

- The heart of the system, vacuum pumps create the necessary negative pressure (vacuum) within the waste piping network. These pumps maintain a continuous vacuum level, ensuring that waste is swiftly and effectively transported through the pipes.

B. Vacuum Interface Boxes:

- Specially designed interface boxes fitted with level sensors or actuated manually by operatros. When activated, the vacuum valve opens, and the waste is instantly sucked into the vacuum piping system. This action is quick and uses significantly less water compared to conventional gravity-based transport methods.

C. Vacuum Valves:

- Located at various collection points (interface boxes), these valves control the entry of waste into the vacuum piping network. They open briefly when waste needs to be moved, allowing it to be drawn into the system by the vacuum pressure.

D. Vacuum Piping Network:

- A network of durable, airtight pipes that transport waste from the collection points to the central waste holding tank or treatment system. The pipes are designed to maintain the vacuum and are typically smaller in diameter compared to gravity-based systems, making them easier to install in confined spaces.

E. Holding Tank:

- Waste from the vacuum piping system is deposited into a collection tank, which stores the residue until it can be processed by the onboard sewage treatment plant (STP) or pumped ashore for disposal.

F. Sewage Treatment Plant (STP):

- An optional but often integral part of the system, the STP processes the collected waste, treating it to meet environmental discharge standards before it is safely released overboard. In some cases, the waste is held until it can be discharged at port.

G. Control System:

- A centralized control panel monitors the operation of the vacuum pumps, vacuum levels, and valve functions. This system ensures the vacuum is maintained throughout the network and alerts the crew to any malfunctions or blockages.

The utilization of vacuum-based waste collection systems typically provides the following advantages:

A. Water Efficiency:

- Vacuum toilets use a fraction of the water required by traditional toilets, significantly reducing the overall water consumption and wastewater generation onboard.

B. Flexible Installation:

- The vacuum system’s ability to transport waste over long distances and through complex routing paths makes it ideal for modern ship designs, where space is often constrained.

C. Improved Hygiene:

- The rapid removal of waste reduces the risk of odor and contamination, contributing to better onboard hygiene and living conditions.

D. Environmental Compliance:

- By reducing wastewater volume and improving waste management efficiency, the system helps ships comply with international environmental regulations, such as MARPOL Annex IV, which governs the discharge of sewage from ships.

E. Space Efficiency:

- Smaller pipe diameters and flexible routing allow for more efficient use of space, which is particularly valuable in the confined environment of a ship.

We can provide the following engineering services associated with the design and installation of a vacuum-based waste collection system.

- Feasibility Study and Concept Design:

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

- Detailed Engineering Design:

- Process engineering and equipment sizing

- Piping and Instrumentation Diagrams (P&IDs)

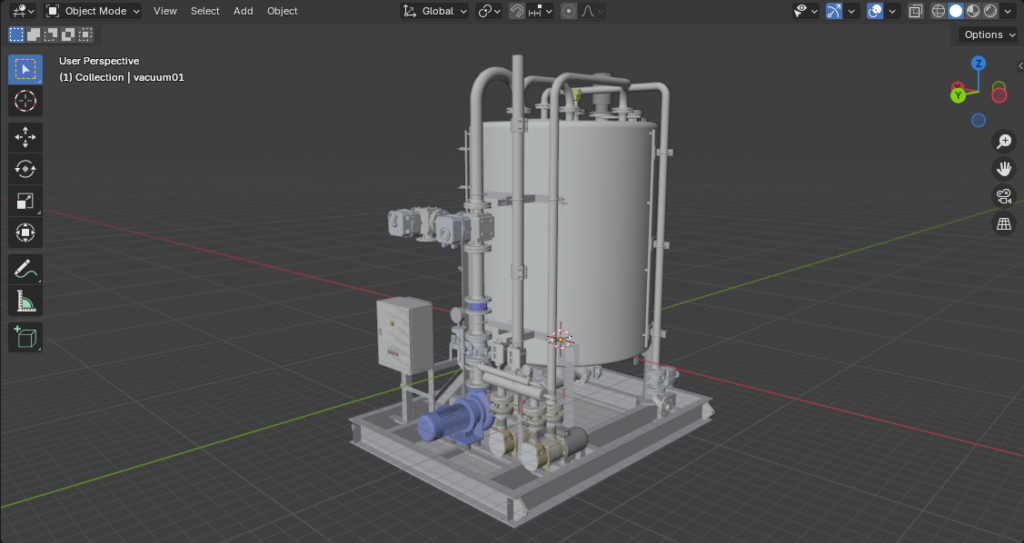

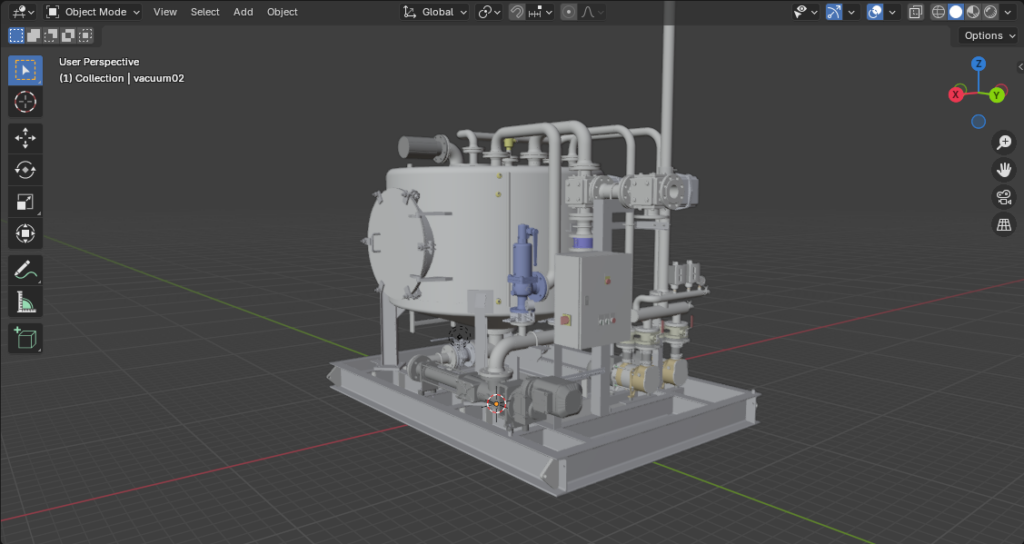

- 3D modeling of the equipment layout

- Electrical system design and integration

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing ship systems (e.g., power, water)

- Modification of existing piping systems

- Safety and Risk Engineering:

- Failure Mode and Effects Analysis (FMEA)

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Analysis of the collection system’s environmental benefits

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design:

Vacuum-based waste collection systems are commonly used on a variety of ships, including cruise ships, ferries, naval vessels, and large commercial vessels. They are particularly advantageous in ships where minimizing water usage and maintaining high hygiene standards are critical, such as passenger ships and offshore platforms. Further information regarding the installation of vacuum-based waste collection systems can be found through the following link.