Drill cuttings reinjection is an environmentally friendly method of disposing of drill cuttings and associated fluids generated during offshore drilling operations.

This process involves grinding the cuttings into small particles, mixing them with seawater or other fluids, and injecting the slurry into a suitable subsurface formation.

The process can be broken down as follows:

a) Collection and Preprocessing:

-

- Drill cuttings are collected from shale shakers and other solids control equipment

- Cuttings are screened to remove oversized particles

- Oil-based mud is recovered for reuse where possible

b) Grinding:

-

- Cuttings are fed into a grinding unit

- Particles are reduced to an average size of 250-300 microns

- This ensures proper slurry formation and prevents plugging during injection

c) Slurry Preparation:

-

- Ground cuttings are mixed with seawater or produced water

- Slurry concentration typically ranges from 20-30% solids by volume

- Chemical additives may be included to adjust viscosity and prevent settling

d) Pumping and Injection:

-

- High-pressure pumps force the slurry down a dedicated injection well

- Injection pressures can reach 10,000 psi or more

- Injection rates vary but typically range from 50-200 barrels per minute

e) Subsurface Disposal:

-

- Slurry is injected into a porous, permeable formation

- Target formation is usually deeper than producing zones

- Hydraulic fracturing may be used to create or enhance injection pathways

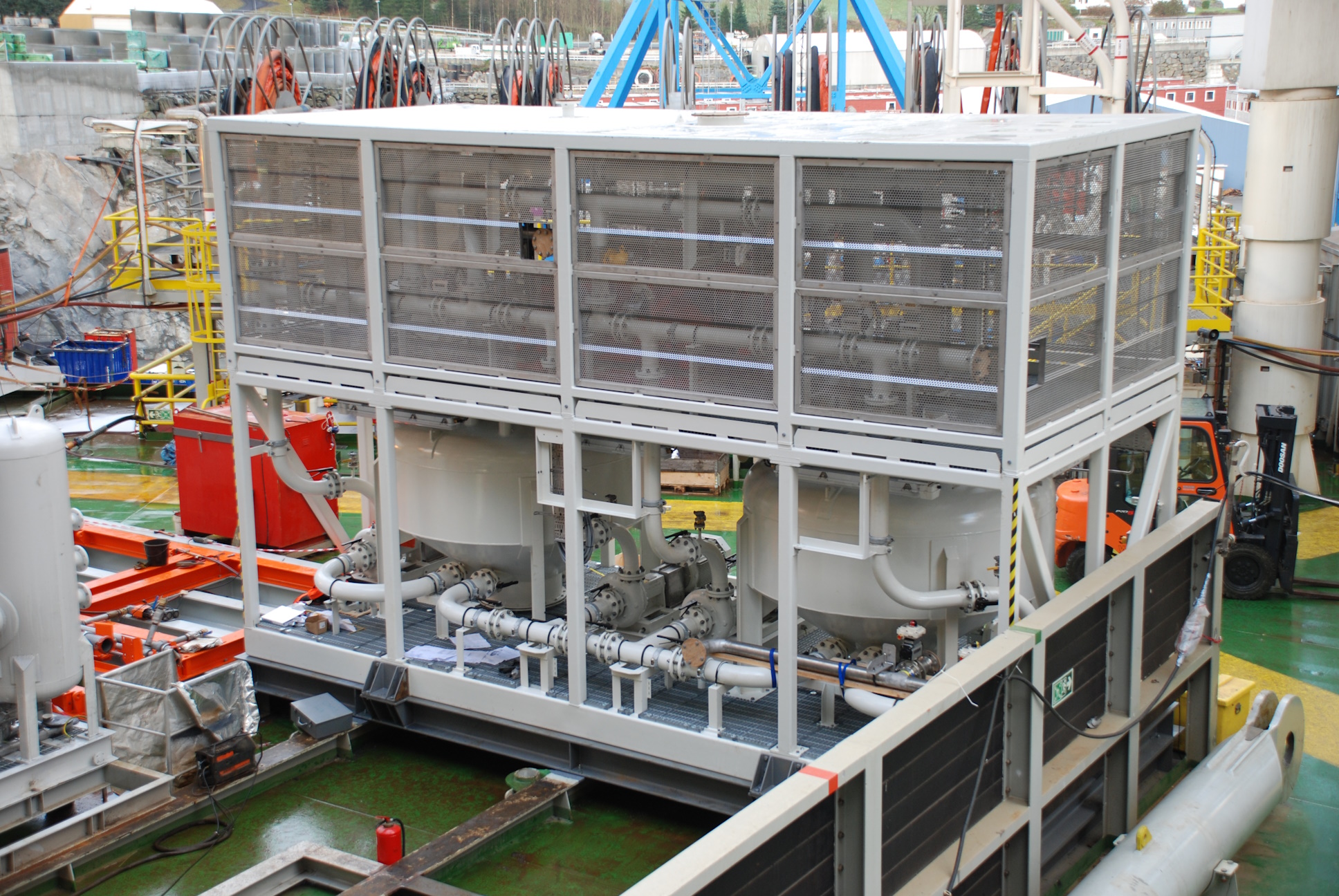

We can provide the following engineering services associated with the design and installation of a Cuttings Reinjection System (CRI).

- Feasibility Study and Concept Design:

- Rig-specific analysis for CRI system integration

- Evaluation of space availability and weight considerations

- Preliminary process flow diagrams

- Conceptual layout designs

- Initial cost estimates and project timeline

- Detailed Engineering Design:

- Process engineering and equipment sizing

- Piping and Instrumentation Diagrams (P&IDs)

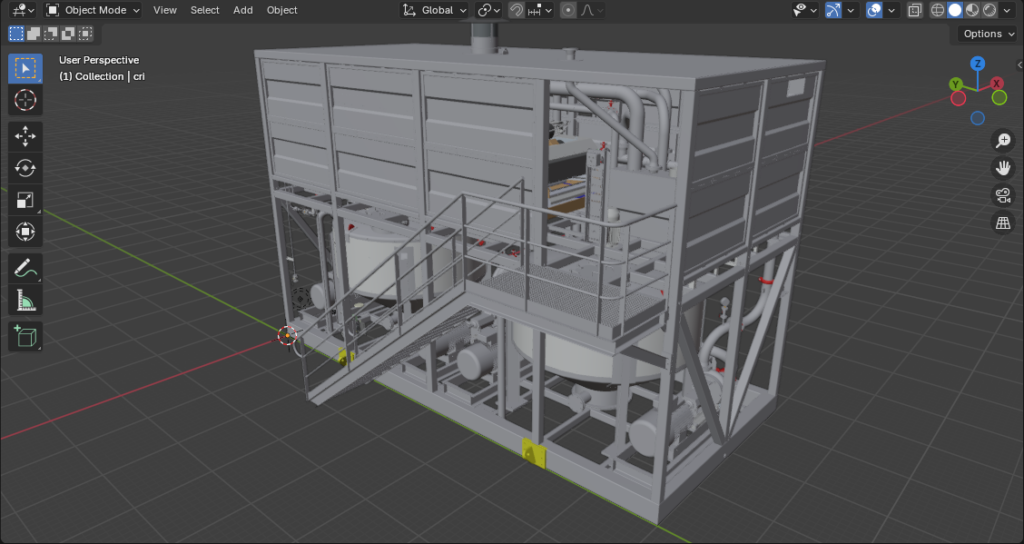

- 3D modeling of the CRI system layout

- Structural analysis for rig modifications

- Electrical system design and integration

- Equipment Specification and Procurement Support:

- Development of technical specifications for major equipment

- Vendor evaluation and selection assistance

- Review of vendor documentation and drawings

- Structural Modifications Design:

- Design of new foundations or support structures for CRI equipment

- Reinforcement designs for existing structures if required

- Finite Element Analysis (FEA) for critical structural components

- Integration Engineering:

- Interface design with existing rig systems (e.g., power, water, mud systems)

- Modification of existing piping systems

- Safety and Risk Engineering:

- Hazard and Operability (HAZOP) studies

- Failure Mode and Effects Analysis (FMEA)

- Safety Integrity Level (SIL) assessment

- Explosion risk assessment and zoning studies

- Regulatory Compliance and Classification:

- Liaison with classification societies

- Preparation of documentation for class approval

- Development of operational procedures to meet regulatory requirements

- Installation Planning:

- Development of detailed installation procedures

- Creation of work packages for shipyard or offshore installation

- Lift plans for major equipment

- Installation sequence optimization

- Commissioning and Start-up Support:

- Development of commissioning procedures

- Supervision of installation and commissioning activities

- Performance of system tests and trials

- Troubleshooting and optimization support

- Documentation and Training:

- Preparation of operating and maintenance manuals

- Development of crew training programs

- Environmental Impact Assessment:

- Analysis of the CRI system’s environmental benefits

- Support for environmental permit applications

- Project Management:

- Overall project scheduling and coordination

- Cost control and progress reporting

- Quality assurance and control

- Lifecycle Support:

- Development of maintenance and inspection schedules

- Optimization studies for long-term operation

- Technical support for system upgrades or modifications

- Feasibility Study and Concept Design:

These engineering services cover the entire spectrum of implementing a CRI system on a drilling rig, from initial concept to installation and ongoing support, with a goal to ensure a safe, efficient, and compliant integration of the CRI system into the rig’s existing operations.

Please follow this link to download our brochure showcasing typical scopes of supply.