The use of a finely tuned language model in equipment maintenance offers several significant benefits that can enhance efficiency, accuracy, and overall operational effectiveness.

A finely tuned language model can significantly enhance equipment maintenance through its ability to integrate and analyze diverse data sources, merging valuable information such as maintenance and service manuals, reports from service engineers, and feedback received from customers, to name but a few.

Here’s how it contributes to the process:

- Access to equipment manuals: The model extracts precise technical information from manuals, aiding in identifying potential issues early and ensuring adherence to best practices.

- Incorporation of service engineer feedback: By analyzing feedback, the model identifies common problems or areas needing improvement, enhancing maintenance strategies.

- Customer reviews insight: Understanding customer concerns allows for proactive addressing, anticipating needs, and improving equipment reliability based on real usage data.

Broadly speaking, the process involves collecting and preparing data, fine-tuning a specific language model, integrating it into tools, enabling real-time support, and continuously improving based on feedback. This structured approach ensures the model delivers precise, contextual, and actionable guidance for equipment maintenance.

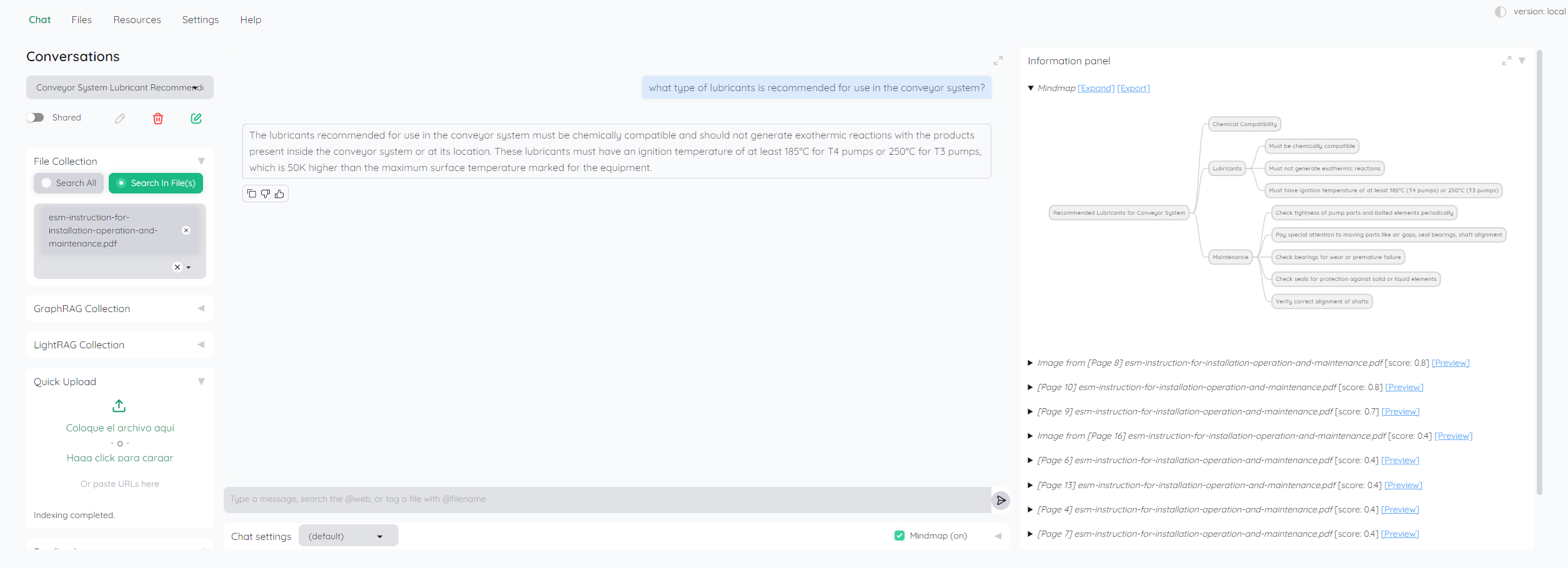

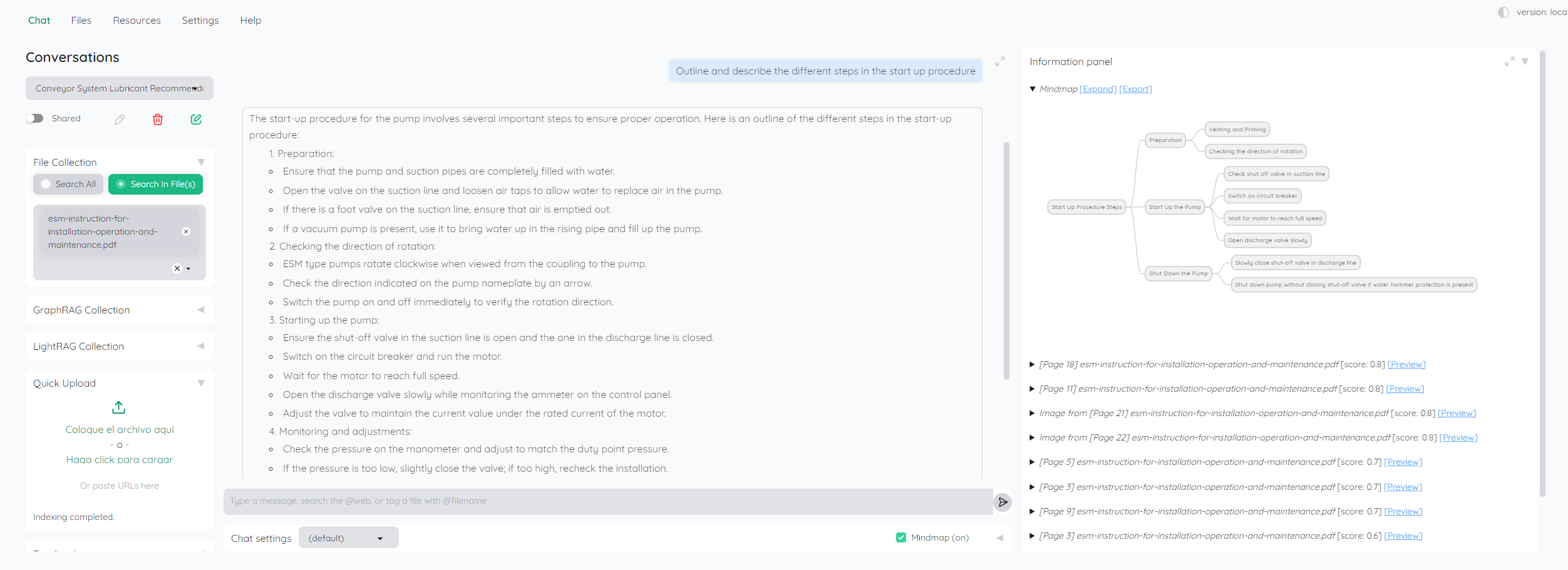

The screenshot below shows a sample interaction between an user and a generalistic (ie, non-finely tuned) language model using Retrieval-Augmented Generation, a much simpler process that is however sufficient to visually demonstrate the advantages of this type of expert system.

Retrieval-Augmented Generation (RAG) is the process of optimizing the output of a large language model, so it references an authoritative knowledge base outside of its training data sources before generating a response. On this particular case, the language model has access to a simple maintenance model of a chemical pump.

For an equipment such as this one, a finely tuned language model could:

- Interpret operational data and maintenance logs.

- Suggest specific maintenance tasks for wear-prone components.

- Highlight design flaws based on recurring feedback from multiple users.

- Enable engineers to quickly diagnose problems by querying, “Why is pump model X overheating under load?”

- Suggest specific maintenance procedures in real time based upon consolidated sources and authoritative references.

In essence, fine-tuned language models bridge the gap between vast amounts of data and actionable insights, enhancing both the effectiveness and efficiency of equipment maintenance processes.

The use of a finely tuned language model in equipment maintenance offers several significant benefits that can enhance efficiency, accuracy, and overall operational effectiveness, benefits such as:

- Access to Technical Information: A language model can quickly and efficiently extract detailed information from equipment manuals, reducing the time spent manually searching through vast documentation.

- Feedback Analysis: By analyzing feedback from service engineers, the model can identify recurring issues or areas for improvement, leading to optimized maintenance practices.

- Customer Insights: Incorporating customer reviews provides real-world insights into equipment performance, helping to anticipate and address potential problems before they become major issues.

- Efficiency and Proactiveness: The model can process information rapidly, enabling faster response times to unexpected issues and minimizing downtime.

- Reduction of Human Error: Consistency in handling complex tasks through AI can reduce errors that might arise from manual processes.

- Predictive Maintenance: Utilizing historical data and feedback, the model can predict equipment failures proactively, allowing for scheduled maintenance at optimal times.

- Insightful Reporting: The ability to generate reports based on analyzed data provides valuable insights into equipment performance, aiding informed decision-making and resource allocation.

- Scalability: The model can handle diverse inputs efficiently, making it suitable for large-scale operations as the number of machines increases.

- Cost-Effectiveness: By reducing downtime and labor costs associated with manual data analysis, the long-term benefits of a language model investment are significant.

- User Experience Enhancement: Seamless integration into existing systems improves workflow without causing disruptions, ensuring efficient operational flow.

While challenges such as potential over-reliance on AI, specialized knowledge gaps, and the need for continuous data updating exist, these can be mitigated with proper training and integration strategies. Overall, a finely tuned language model has the potential to revolutionize equipment maintenance by making it more efficient, accurate, and proactive.

Find out how we can help, contact us for further information.