Safety is the number one priority and concern onboard oil & gas installations. No other factor comes close when outlining the basic operational criteria and design principles, with the final goal of reducing as far as possible the occurrence of accidents related to operations, and to limit their consequences.

By coordinating different disciplines during the development of engineering packages, we can provide a solution where risks are identified and consequences are mitigated through passive and active means which are incorporated into the general design complementing the operational requirements.

Fire risk is one of the key hazards onboard drilling and production units, as fire can ignite even if all precautions have been taken given the potential presence of flammable products and atmosphere in numerous parts of the installation. It can also start in other areas not directly involved in operations, manned or unmanned, such as accommodation or equipment rooms.

Uncontrolled fire, and the resulting smoke, are extremely dangerous and their progression must be stopped as soon as possible in a safe, controlled manner. Design principles must emphasize the necessity of minimizing the risk so as to protect crew and critical equipment in unexpected situations.

Where the risk turns to certainty, designs must ensure that the fires are contained and promptly extinguished through the combined effect of different disciplines such as architectural (fire rating of bulkheads and decks), electrical (fire detection and alarm) and mechanical (containment of spread through fire dampers, and extinguishment through manually operated or automatic systems).

We can assist in the analysis and assessment of the potential risks, and advise on suitable solutions to reduce chances of occurrence.

Area classification is a method of analysing and classifying the environment where explosive gas atmospheres may occur. The main purpose is to facilitate the proper selection and installation of equipment to be used safely in that environment, taking into account the properties of the flammable materials that will be present.

It is acknowledged that such environments may be comprised of any concentrations of flammable gases, vapors, mists or combustible dusts. Hazardous areas are classified into zones based on an assessment of the frequency of the occurrence and duration of an explosive gas atmosphere.

Along those lines, we can assist in the analysis and classification of zones, development of zone maps, and selection of equipment suitable for operation in the different hazardous zones which have been classified.

Where technically feasible, alternatives can be provided to mitigate the inherent risk by reducing the frequency of the occurrence and/or duration of an explosive gas atmosphere.

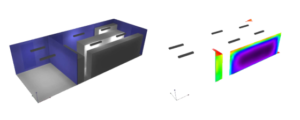

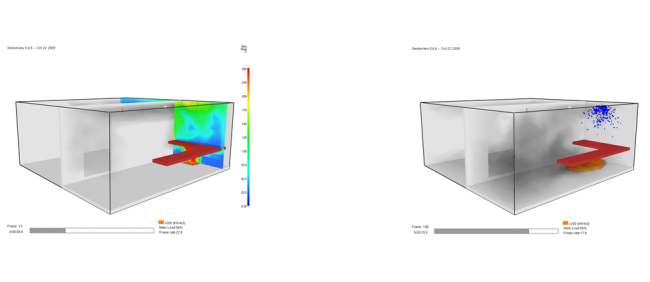

Heating, Ventilation and Air Conditioning (HVAC) systems play a significant role in safety by providing suitable conditions for the crew and protecting crew and equipment from hazards originated in the drilling and production process.

In addition, they enable compliance with HSE requirements by contributing to comfort work conditions, and contribute to energy efficiency in the installation. This is specially important considering the harsh environmental conditions typically present in the exterior of drilling and production installations, typically located offshore in the open sea.

In coordination with the development of engineering packages for other disciplines, such as architectural (insulation of bulkheads and decks) or fire engineering (installation of gas detection devices or fire dampers in air ducts), we can assist in the development of suitable HVAC systems by analyzing heat loads and air change rate requirements for manned or unmanned spaces.

Another discipline of interest when ensuring suitable working conditions and mitigating operational risks is the implementation of suitable lighting arrangements in work environments (both interior and exterior). In addition, properly engineered lighting solutions prove essential in special purpose installations or in evacuation routes.

In this field, we can specify and select suitable products and lighting arrangements, and carry out photometric calculations (average illuminance, uniformity rations, etc) so as to ensure that conditions are appropriate for normal operation, as well as during emergency scenarios.