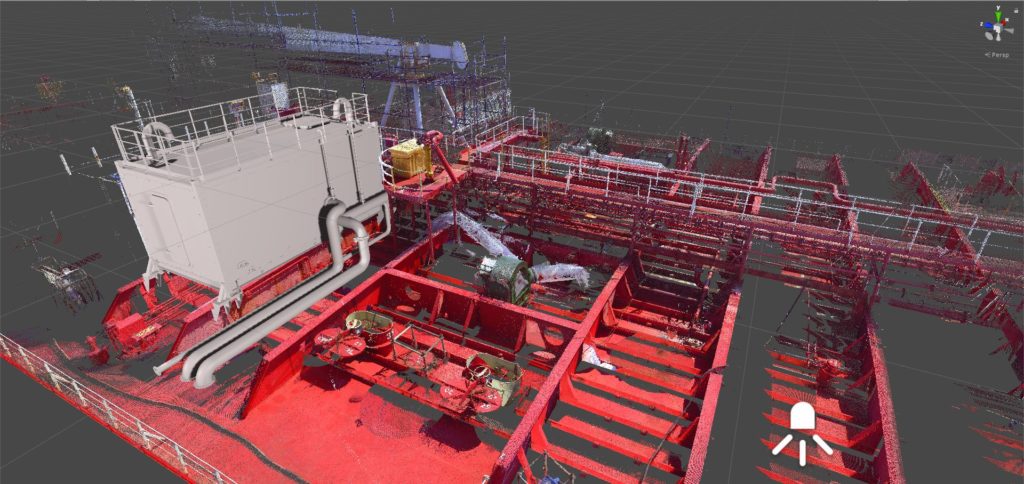

Project reference: Design of a preassembled deckhouse and outfitting of a 1.500 m3/h capacity ballast water treatment system on the main deck of an oil tanker.

The IMO’s Ballast Water Management Convention has entered into force on September 8th, 2017. Under the Convention, all ships in international traffic are required to manage their ballast water according to a ship-specific ballast water management plan.

The ballast water management standards are being phased in over a period of time, with new ships being required to meet the ballast water treatment standard. Existing ships should exchange ballast water mid-ocean but they will need to meet the ballast water treatment standard by the date of a specified renewal survey. Eventually, most ships will need to install an on-board ballast water treatment system.

In order to ensure their ships comply with the rules and regulations set by IMO regarding Ballast Water Management, several shipping operators have started implementing ballast water treatment systems on their ships. The proper treatment of ballast water, as required by the IMO, actively removes, kills or neutralises organisms prior to discharge.

Please follow this link to download our brochure showcasing typical scopes of supply.

We can supply design and engineering packages based upon available documentation, drawings, and onboard survey results, to Class and customer approval including:

- System layout/ arrangement in deckhouse.

- Structural arrangement drawings (foundations, pipe supports, etc).

- Architectural drawings (insulation and fire rating).

- Installations (ventilation, fire detection, etc).

- Schematic and P&IDs.

- Piping arrangement and isometric drawings.

- Material Take Off lists.

- Electrical block drawings.

- Installations notes and drydock specification.

We can supply design and engineering packages based upon available documentation, drawings, and onboard survey results, to Class and customer approval including:

- System layout/ arrangement in engine room.

- Structural arrangement drawings (foundations, pipe supports, etc).

- Schematic and P&IDs.

- Piping arrangement and isometric drawings.

- Material Take Off lists.

- Electrical block drawings.

- Installations notes and drydock specification.