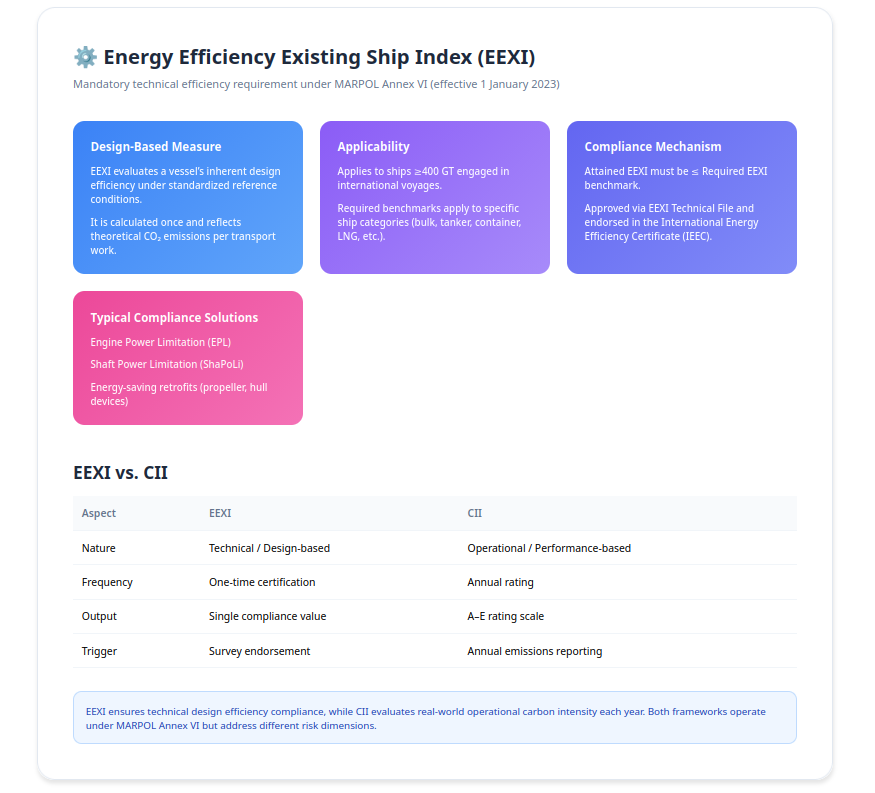

The Energy Efficiency Existing Ship Index (EEXI) is a mandatory technical measure introduced under MARPOL Annex VI by the International Maritime Organization. It entered into force on 1 January 2023 and applies to existing ships engaged in international voyages. Unlike the Carbon Intensity Indicator (CII), which evaluates annual operational performance, EEXI assesses a vessel’s inherent technical design efficiency under standardized reference conditions.

EEXI is not an operational rating. It is a one-time technical compliance requirement intended to align the existing fleet with energy efficiency benchmarks comparable to those applied to new ships under the Energy Efficiency Design Index (EEDI). Once verified and endorsed, EEXI compliance is reflected in the vessel’s International Energy Efficiency Certificate (IEEC).

What is EEXI?

EEXI represents a calculated measure of a ship’s theoretical CO₂ emissions per transport work under defined reference conditions. It is derived from technical parameters including:

Main engine maximum continuous rating (MCR) and limited power settings

Specific fuel consumption of main and auxiliary engines

Carbon emission factor of the fuel used

Ship reference speed under standardized conditions

Cargo capacity (deadweight tonnage or gross tonnage, depending on vessel type)

The attained EEXI must be less than or equal to the required EEXI value prescribed for the vessel’s category and size. Required values are based on reference lines originally developed for EEDI and adjusted through reduction factors depending on ship type and capacity band.

Applicability

EEXI applies to ships of 400 gross tonnage and above engaged in international voyages. However, required benchmark values are defined only for certain ship categories specified in MARPOL Annex VI, including bulk carriers, tankers, gas carriers, container ships, general cargo ships, refrigerated cargo carriers, combination carriers, LNG carriers, and certain passenger ships. Other ship types may still require documentation but may not have a reduction benchmark assigned.

Compliance was required at the first annual, intermediate, or renewal survey on or after 1 January 2023. Approval of the EEXI Technical File and endorsement of the IEEC confirm compliance. EEXI is not recalculated annually unless substantial modifications affecting energy efficiency occur.

EEXI vs. CII

Understanding the distinction between EEXI and CII is critical for fleet strategy.

EEXI is a design-based, technical compliance metric calculated once under standardized conditions. It reflects the vessel’s theoretical efficiency potential.

CII, by contrast, is an annual operational performance metric based on actual fuel consumption and transport work achieved during the calendar year. CII results in an A to E rating and may trigger corrective action plans if performance deteriorates.

In practical terms, EEXI determines whether a vessel is technically permitted to operate from an efficiency design standpoint, while CII determines whether the vessel’s operational deployment remains compliant year by year.

Calculation Framework

The attained EEXI is calculated using an IMO-prescribed formula that incorporates main engine power (often limited to 75 percent of MCR), auxiliary engine power, specific fuel consumption values, fuel carbon factors, reference speed, and ship capacity. The methodology is documented in detail in the EEXI Technical File and must be verified by a recognized organization or classification society.

Because the formula integrates reference speed and engine power, many older vessels achieve compliance by implementing Engine Power Limitation (EPL) or Shaft Power Limitation (ShaPoLi) measures. These solutions reduce the maximum available propulsion power and therefore lower the calculated CO₂ emissions at reference conditions.

The Compliance Challenge

Ships designed before modern efficiency standards often have higher installed engine power relative to their required EEXI benchmark. Without corrective measures, such vessels may exceed required values. The most common compliance solution has been Engine Power Limitation, but this introduces operational considerations, particularly regarding maneuverability, weather avoidance, and commercial speed requirements.

For certain vessel segments, especially container ships with historically high installed power, compliance required careful assessment of power limitation strategies, propeller optimization, or other efficiency retrofits.

What we do: We provide comprehensive EEXI compliance advisory and technical support services.

A. EEXI Calculation and Technical File Preparation

- We conduct detailed technical data collection, including engine specifications, sea trial data, reference speed validation, and fuel consumption parameters. We prepare or verify the EEXI Technical File in accordance with IMO guidelines and coordinate with classification societies for approval.

B. Gap Assessment

- We compare attained EEXI values against required benchmarks and identify compliance margins or shortfalls. Where gaps exist, we quantify the magnitude of adjustment required and evaluate alternative compliance pathways, including engine power limitation scenarios and technical modifications.

C. Improvement Measures

- Where modification is necessary, we assess options such as Engine Power Limitation, Shaft Power Limitation, propeller upgrades, hull efficiency devices, and other energy-saving technologies. Each option is evaluated for technical feasibility, operational impact, and cost-effectiveness.

D. Certification Support

- We support coordination with recognized organizations during survey attendance, facilitate documentation review, and ensure endorsement of the International Energy Efficiency Certificate.

In summary, EEXI is a foundational technical compliance requirement that establishes whether a vessel’s design efficiency meets internationally mandated standards. While it is not an annual rating system, its implications for engine power availability, commercial speed, and operational flexibility are significant. Proper technical assessment ensures compliance without unintended operational constraints.