Intelligent process simulation is a cutting-edge technology revolutionizing industrial operations by combining advanced modeling tools, real-time data, and artificial intelligence. This technology allows engineers and decision-makers to create dynamic, digital representations of industrial processes, enabling enhanced design, analysis, and optimization.

At its core, intelligent process simulation replicates physical processes and systems within a virtual environment. Here’s how it functions:

- Data Integration: Real-time data from sensors, IoT devices, and historical databases feed into the simulation platform, ensuring the model reflects actual operating conditions.

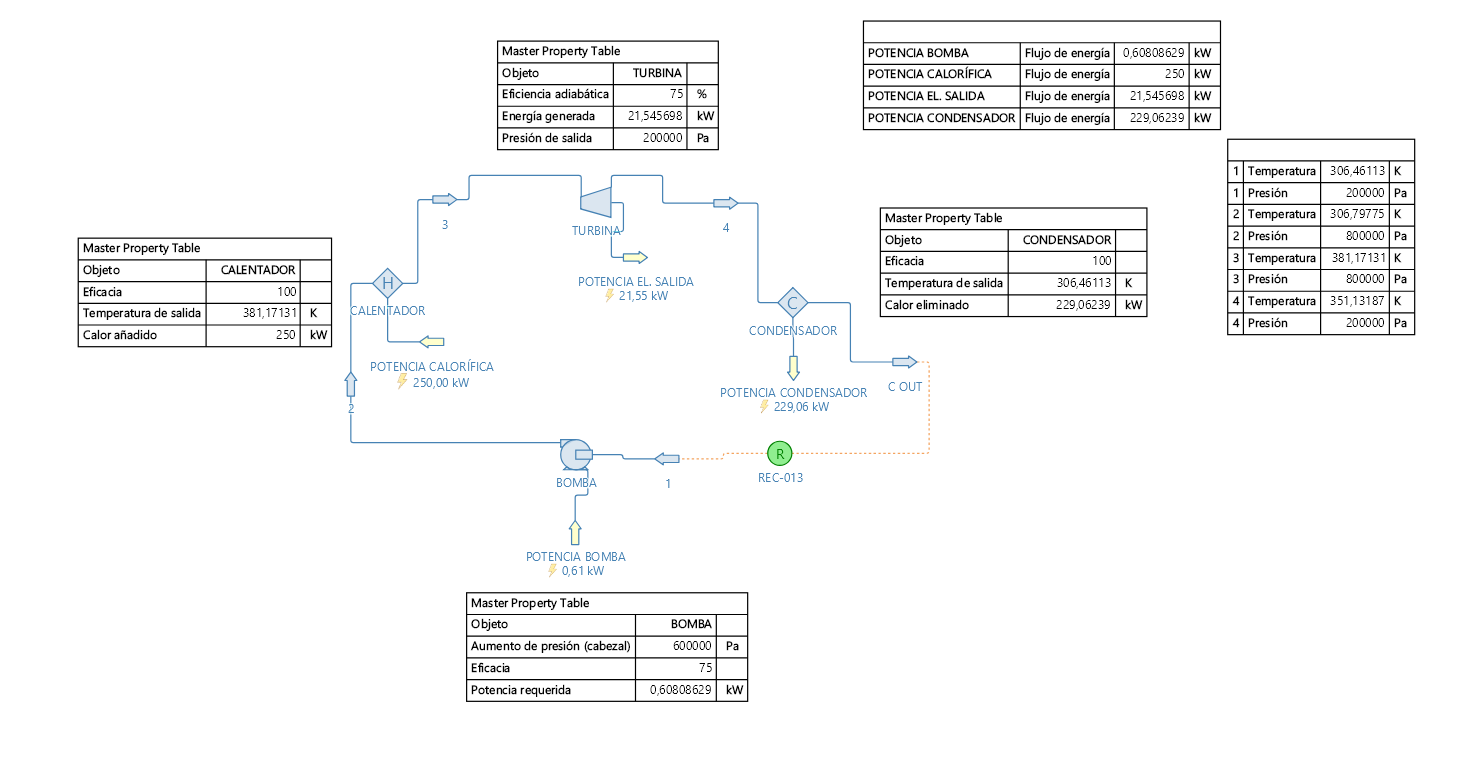

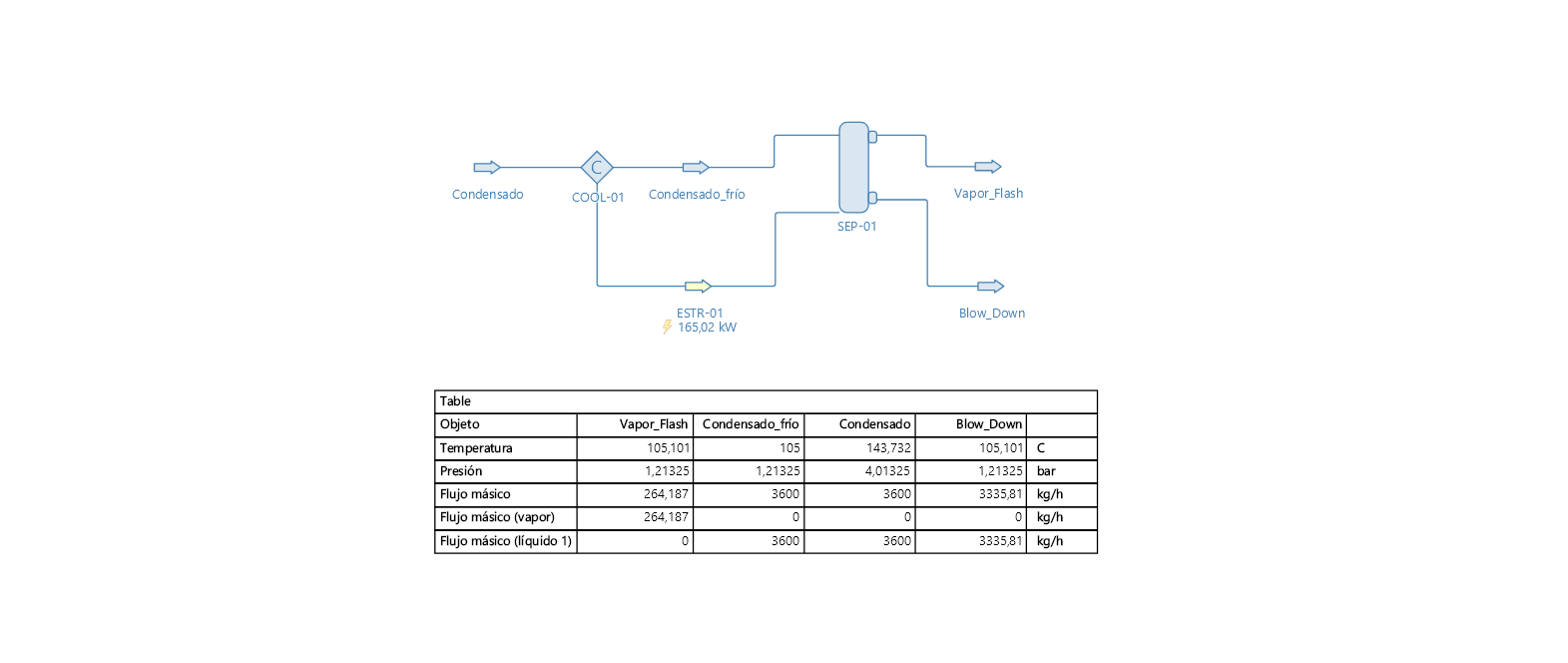

- Process Modeling: Using physics-based principles and mathematical algorithms, the simulation accurately represents how materials, energy, and fluids behave in the system.

- AI and Machine Learning: AI algorithms analyze patterns and provide predictive insights, enabling proactive decision-making and adaptation to changing conditions.

- Scenario Testing: The simulation allows users to test “what-if” scenarios, evaluating the impact of different parameters, such as equipment modifications or process changes, without disrupting operations.

The following benefits result from a thorough simulation of a given system:

- Optimized Design: Designs can be tested and verified in a virtual environment, ensuring that systems meet performance requirements before physical implementation.

- Improved Operational Efficiency: Intelligent simulations highlight inefficiencies, enabling targeted interventions to boost productivity and reduce waste.

- Predictive Maintenance: By simulating equipment wear and tear based on real-time data, maintenance activities can be predicted and scheduled, reducing unexpected downtime.

- Enhanced Safety and Compliance: Virtual testing of hazardous scenarios ensures systems are robust and compliant with safety standards.

- Sustainability: Simulations optimize resource usage and reduce emissions, aligning operations with environmental goals.

This technology represents a fundamental shift—from reactive troubleshooting to proactive, data-driven optimization. Intelligent process simulation is not just a tool for the present; it is an essential cornerstone of the industrial future.

Find out how we can help, contact us for further information.