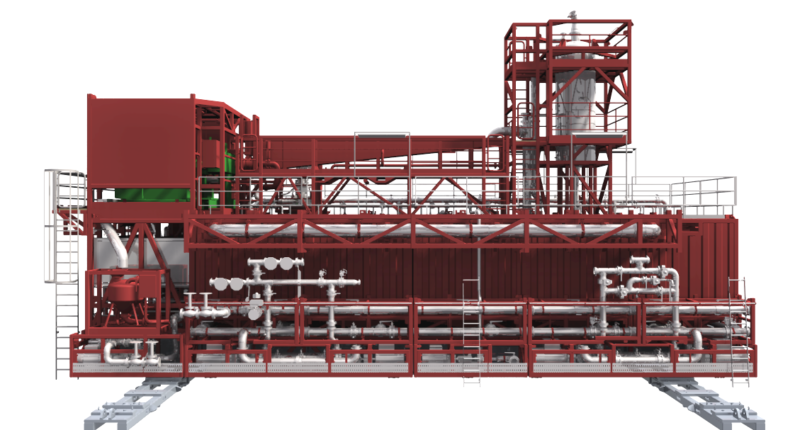

Project reference: Design of a modular plant for storage and treatment of drilling mud, compliant with DNV OS-E101 and 2.7-1/2.7-3 requirements.

Our portfolio includes modules and mechanical packages for the offshore oil and gas industry as well as the offshore wind energy sector. We design and engineer a variety of modules and topside structures for fixed production platforms including process modules, subsea templates, living quarters, control rooms and other engineered packages at clients’ request.

- Compliant with North Sea rules and regulations: Norsok D-001 Drilling Facilities and DNV Offshore Standard OS-E101 Drilling Plant.

- Modules compliant with DNV 2.7-3 as well as OS-E101 during operation.

- Designed to operate within Zone 1 and 2 hazardous areas.

- Designed so as to withstand sour service (NACE MR-0175 and ISO 15156).

- Process piping designed in compliance with ASME B31.3.

What follows is a non-exhaustive list of packages we have developed to date.

- Drilling mud treatment systems.

- Cuttings reinjection systems.

- Chemical injection systems.

- Methanol injection systems.

- Riser gas handling systems.

- Gas scrubbing and inter-cooling systems.

- Sand handling and treatment systems.

- Oil, gas and water separation systems.

- Fuel transfer systems.

Besides developing engineering packages, we can provide technical assistance during the design review process and fabrication. What follows is a non exhaustive list of activities we can undertake to provide support during the fabrication stage.

- Code consulting, compliance with North Sea rules and regulations.

- 3D Modelling and 2D drafting, bill of materials, generation of as built drawings.

- Assistance to material selection, procurement, logistics, customs clearance.

- Revision of welding procedures and welding maps.

- Production of traceability records (material certificates, non destructive testing, mechanical tests, etc).

- Coordination with Certifying Body during design review and production surveys.

- Engineering and production weight control compliant with ISO 19901-5.

- Lifting and handling planning.

- Mechanical testing procedures and witnessing/undertaking.

- Bolt tightening procedures and verification.

- Pipe cleaning and flushing procedures and verification.

- Pressure test procedures and supervision.

- Coating procedures and specifications, coating production tests.

- Assistance to mechanical completion, pre-commissioning check lists and commissioning procedures.